No-Dry Twin Screw Extruder Series Can Handle Multiple Resins

Machine can process a variety of virgin, postconsumer, postindustrial resins and flake without first having to crystallize, dry or change screws.

The MultiRESN twin-screw extruder from Processing Technologies LLC (PTi) features improvements that have been implemented over time to meet industry demands and processing capabilities. The twin-screw extruder is said to be capable of processing a variety of virgin, postconsumer and postindustrial resins and flake, including PET, PLA, PP, PS, PE and other unique blends, without first having to crystallize, dry or change screws.

PTi says the machine offers processors several significant advantages over other machines in the market. Among other things, its compact design (the machine’s L/D ratio has been cut from 52 to 50:1) is said to reduce floor space requirements, while labor and energy usage are minimized or eliminated because predrying is unnecessary. The added capability to process a multitude of resins on one extrusion system leads to greater versatility and opportunities for the processor to meet consumer demands, PTi maintains.

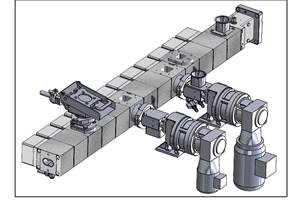

SGTSE MultiRESN 90-mm twin-screw extruder furnished with die assembly. Source: PTi

SGTSE MultiRESN 90-mm twin-screw extruder furnished with die assembly. Source: PTi

A newly configured square barrels design heats up faster with higher heater-to-barrel mass density ratios vs. that of round barrel counterparts, resulting in heat-up times reduced by as much as 30%. Resins (pellet, flake and process scrap) can be immediately introduced into the process without drying, further saving energy while utilizing the most available resources. Furthermore, the starve-fed system means blends, colors and quick changeovers can be accomplished on the fly and in as little as 20 minutes, reducing downtime, maintenance and startup times.

The SGTSE MultiRESN is equipped with PTI’s patented M-ATEX technology, which enables free thermal expansion of the equipment; its TITAN Control system; and RealTIME IV monitoring. This newest machine series features many improvements over past designs, including:

- Targeted Sizes: Machine sizes coincide with processor needs. Model size capacities align with production targets.

- Modular Components: Fully welded modular barrel sections with liquid cooled cores (eliminating 350-plus hydraulic barrel cooling plugs) are engineered with specific metallurgies for extended component life. Additionally, the square barrel segments (two unique nonvented and vented) provide an incremental balanced process profile and cost-effective serviceability.

- Heat Retention: Oven-style barrel guards (integrated thermal guards) provide tool-free access and excellent heat retention.

- Energy Efficiency: Cast bronze and aluminum high-watt density heaters use targeted energy theory to maximize efficiency and overall machine performance.

- High-Torque Rating: Screw elements feature full length inner-splined bores for improved torque ratings.

- Unique Screw Removal: The drive end decouples from the downstream barrel section to permit screw removal out the back for reduced footprint requirements, and ease of service and inspection.

- Stainless Steel: High-vacuum circuits offer all stainless-steel construction to assure long component life and superior performance with toolless-access cleanout hatches.

- Higher Outputs: Overall machine design yields 15%-plus greater production outputs per horsepower, making it highly efficient.

PTi’s has for years represented Bandera’s line of no-dry twin-screw extruders, tradenamed by PTi as the HVTSE series. PTi will no longer import the Bandera machines moving forward, but still services machines it has sold and installed in the U.S.

Related Content

Strategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreOptimizing Melt-Fed Single-Screw Extruders on Compounding Lines

The main problem with melt-fed extruders that are starve-fed is setting the depth of the metering channel. In this scenario, we describe how this problem was solved.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More