New In-Mold Labeling System Launches at K 2022

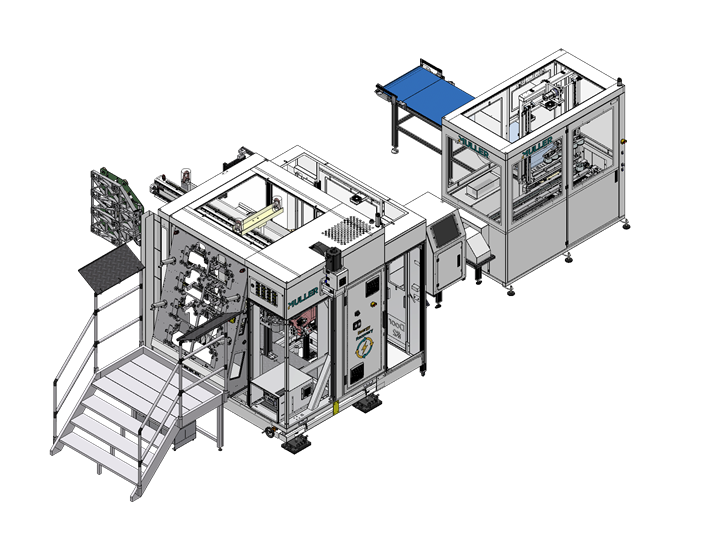

Muller Technology’s IML production cell will produce a round container in an 8-cavity mold with vison inspection and downstream automation.

Mold and automation supplier for thin-wall packaging, Muller Technology, will unveil its latest in-mold labeling (IML) automation technology at K 2022. The IML production cell, which includes vison inspection and downstream automation, will run on a 700-ton injection molding machine at the BMB SpA booth, producing a round container in an 8-cavity mold.

The cell’s output is 100% monomaterial containers composed of a fully recyclable polypropylene (PP) structure, including a wrap-around and bottom PP label from Belgian label maker MCC Verstraete. The high-volume manufacturing cell can produce more than 40 million containers per year for food, dairy and other consumer packaging applications.

Muller says the automation system consumes less energy thanks to an energy recovery system, and its modular design gives it flexibility and allows it to be paired with a case-packaging system. The dynamic entry feature uses artificial intelligence (AI) programming for self-optimization of the robot intrusion between the platens, optimizing total cycle time.

Muller says its mold design minimizes maintenance and increases mold life, providing quick changeout capabilities that allow for fast and safe product changeovers. The IML automation system is also compatible with the Holy Grail 2.0 intelligent sorting system, which enabels label identification for end-of-life classification. The company will build these IML automation systems in the U.S. at its Fort Collins, Colo. facility and in Switzerland at its Conthey plant.

Muller will debut a new IML system at K 2022 built around a BMB injection molding machine.

Photo Credit: Muller Technology

Related Content

-

Conair: Going All In on AI

Conveying with Optimizer, Conair’s new AI-based conveying technology stands to be a true game changer for plastics processors.

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.