Natural Zeolite Acid Scavengers Show Broad Use in Film, Packaging, Molded Parts

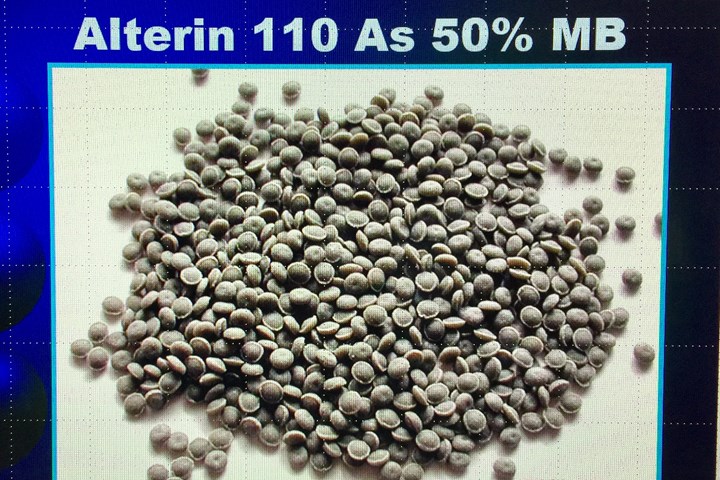

Endex International’s Alterin 110 & 111 aluminum silicates approved for several end-use applications in polyolefins and beyond.

Newly available from Canada’s , a supplier of blowing agent additives for plastics, are two natural zeolites (aluminum silicates) that act as acid scavengers, odor suppressors, molecular extenders, and catalysts which reportedly show promise in several thermoplastic film, packaging and molded parts applications.

The Alterin 110 (28-30 micron) and 111 (10 micron) zeolite products sold in powder form or in master-batch were developed jointly by consulting firm Stabilization Technologies LLC, Charlotte, N.C., and Endex, according to Joe Webster, president of , and well-known technical expert in plastics additives.

In polyolefin agricultural films, they have been shown to retain 30-40% more moisture than synthetic zeolites, and a lower cost, while having significantly higher compounding durability than synthetics for plastics which also results in increased retention of nutrients from the soil. According to Webster, end-use approved plastics applications include:

â–ª Ethylene scavenging in PE film packaging for extended use of fruits and vegetables. These products are sold as masterbatch to convertors of polyolefin films for zip loc or standard bags for packaging and shipping fruits and vegetables. Ethylene scavenging extends the lifetimes of fruits and vegetables.

â–ª Masterbatch carriers for liquids and botanicals for slow stable release in injection molded inserts, bottles and films for retention of flavor and odor in polyolefin packaging. Also, to control and mediate insect vectors stored in bags that reduce post storage of grains and rice.

â–ª Serve as odor suppressants in a broad range of packaging and medical packaging and device applications, from extruded and thermoformed film to injection and blow molded rigid packaging—ranging from polyolefins and PET to nylons and ABS. Used for end-use applications that require control of both organoleptic odors and composites of vulcanized rubbers and fillers.

â–ª Serve as an organo-mineral pigment filler (OMPF), to plastics to compliment or replace other workhorse fillers. OMPF allows for the control and end use of borderline dyes that can be integrated into the zeolite to stabilize its limited thermo-oxidative, thermal stability and photo-oxidative stability in molded plastics. This includes infrared dyes.

â–ª Used to encapsulate and stabilize cationic dyes against both thermal and photo-oxidative degradation in plastic films, molded parts, and fiber. OMPF are applicable to all polyolefins, condensation polymers Nylon and PET, PBT, PC and styrenics (HIPS, ABS).

â–ª Used in the production of stabilizers, photo-catalysts, thermal catalysts for plastics and coatings. The catalytic properties of Alterin are synergistic with other similar zeolitic structures. Endex International and Stabilization Technologies LLC have discovered unpredicted photocatalytic activities with natural Alterin in combination with select materials.

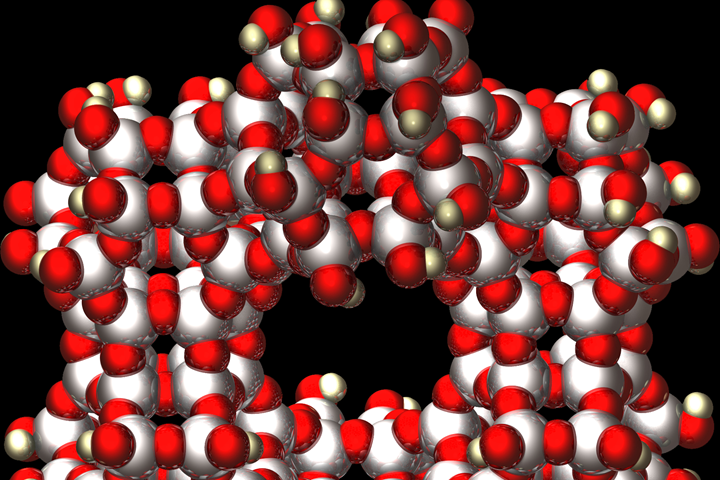

Alterin framework and nanocavities have served as support or hosts for photoactive materials or traces of transition metals functioning as photoactive sites for catalyzing decomposition and oxidation reactions in the gas phase. Furthermore, low-temperature plasma treatments can be used to activate zeolite for environmental application by increasing hydroxyl groups on the surface (Si-OH, Al-OH).

â–ª Used to integrate military-grade infrared dyes, produce antimicrobial, antifungal, algicides via metal exchange reactions. These materials can be converted into masterbatch compounds using appropriate carriers for the end-use application. End-use applications for agricultural film , molders and the powders themselves can be used in canisters for automotive applications to control nitrous oxide pollutants from exhausts.

â–ª Used in flame retardant intumescent polyolefin composites as a synergistic agent to enhance LOI.

Webster notes that the use of these natural zeolites in plastic agricultural and packaging films have been shown to reduce degradation rates and neutralize anthropogenic acids which are known to significantly reduce the lifetime and appearance quality of all pigmented and unpigmented plastics, and to destroy their UV stabilization. Moreover, in thick-section plastics, they have been shown to control rates of degradation, increase physical properties, neutralize acids and stabilize additive UV stabilization systems. In addition Alterin hybrid exchanged systems provide other synergisms in films and agricultural and aquaculture applications including control of molds and algae formation.

The Alterin zeolites have also been shown to reduce VOC emissions in plastics formulations, and significantly reduce solvent odors and odors associated from degradation products in recycled plastics. Said Webster, “Studies by Stabilization Technologies using GCMS and p-NMR of PAH, VOC, HAPS and a host of complex odor problems has used these techniques to solve global issues related to complex filled backings and composites using various fillers known to increase odors. Today using Alterin and other hybrids of the same chemistry odor issue are now mediated or eliminated.

Related Content

Masterbatches Reduce Gloss in PLA and PETG 3D Printed Products

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MoreNon-PFAS Mold Release for High-Temperature Polymers

Avient’s Evoluscend is designed to boost manufacturing efficiency.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More