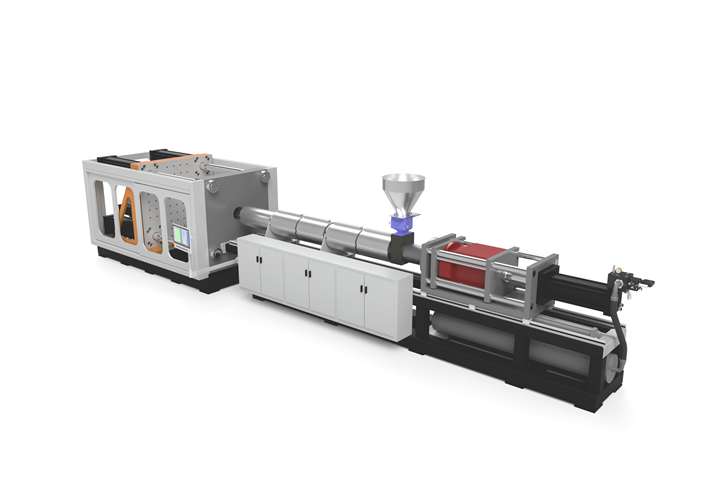

Medium-Pressure Machine for Structural Foam

Wilmington’s 500-ton model is suited to both solid molding and thin-wall structural foam.

Wilmington Machinery has launched the Lumina MP500 medium-pressure injection machine, a 500-ton version of the MP800 introduced several years ago (Feb. ’17, Keeping Up). Though capable of solid molding, the MP500 is aimed primarily at structural foam parts for automotive, recreational, material-handling and enclosure parts. Compared with Wilmington’s low-pressure foam presses, the MP500 has twice the injection pressure and clamping force, suitable for molding thin-wall or core-back foamed parts. But in common with the firm’s low-pressure machines, the MP500 has a 30:1 L/D plasticating unit capable of compounding additives and processing 100% recycled materials, as well as being ported for direct gas injection.

Like the MP800, the new, smaller model has a reciprocating screw as standard with two-stage (screw/plunger) injection optional. The reciprocating-screw version comes with a reportedly unique inline accumulator that offers double the shot volume typical for a given screw diameter while retaining first-in/first-out performance. Shot size for foam is 40 in.3 (approx. 15 lb of HDPE); for solid molding it’s 240 in.3 (approx. 7.5 lb HDPE).

The two-platen clamp has tiebar clearance of 42 × 42 in. and usable mold space of 60 × 42 in. Hydraulic ejection is standard.

Related Content

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

Use These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.