Materials: EPP Foam with Improved Surface Properties and Optimized Filling Behavior

BASF’s new expanded PP foam Neopolen P 9235+ is designed for components with a high-quality look to be used in the automotive and building industries.

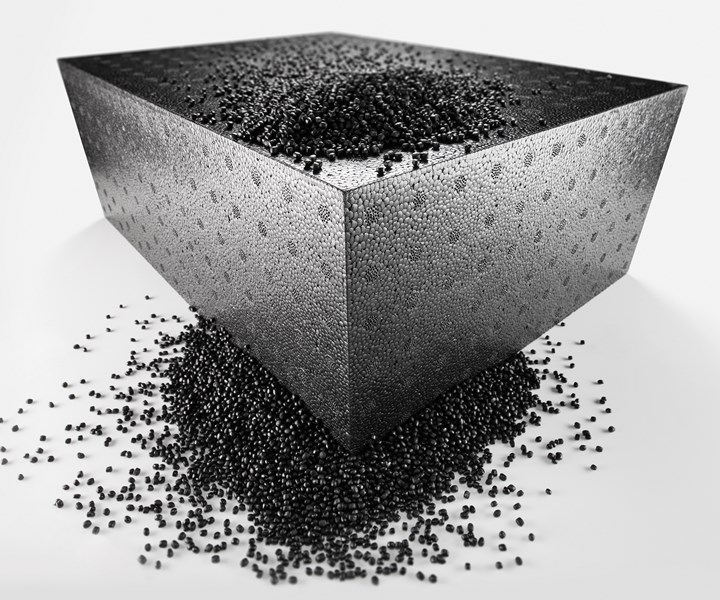

The Neopolen product range of expanded polypropylene foam (EPP) from BASF (U.S. office in Florham Park, N.J.) has a new addition that is said to offer improved surface properties and more. Compared to the available grades, the new Neopolen P 9235+ grade is said to offer improved surface properties, a color impression deepened by 20% and optimized filling behavior in manufacturing. (Neopolen is a recyclable EPP consisting of expanded, mainly closed-cell foam particles free from chemical blowing agents.)

Parts made of Neopolen P 9235+ reportedly generate considerably less friction noise. The black particle foam is suitable for automotive parts and dunnage trays subject to impact stress as well as for construction and protection applications in heating, ventilation and air conditioning systems. Neopolen P 9235+ is listed in the automotive industry’s material data system IMDS and is initially being made available in Europe. This new standard grade will gradually replace the well-established Neopolen P 9235 and will evolve into a new product family including specialty grades in the medium term.

Neopolen P 9235+ enables high-quality, smooth surfaces which is an advantage for visible components such as trunk liners in cars. The improved color depth by 20% was proven in tests: the special laboratory unit simulates human color perception according to the CIE 1931 color system (CIE: French for: International Commission on Illumination) and thus offers an objective and verifiable color result. Further applications of the new particle foam grade include automotive parts such as bumper cores, headrests and armrests. It also serves as housing insulation for heat exchangers and heating units.

Neopolen P 9235+ shows the well-established properties of the Neopolen family. It is characterized by high energy absorption and low weight, good resilience following static and dynamic loading and an essentially unchanged energy absorption after repeated impact load. The new grade reportedly is resistant to chemicals and oils, thermally insulating and has a low water uptake. The foam particles are available as packaged goods or as loose bulk.

Related Content

-

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.