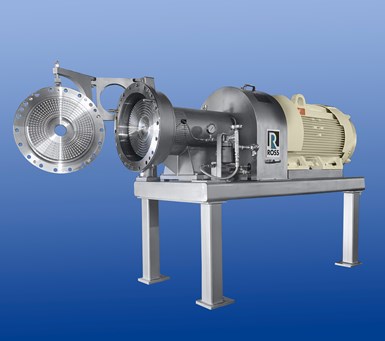

Inline Ultra High Shear Mixer

Designed to deliver exceptional dispersion, emulsification, and homogenization at high throughput.

Ross’ Inline Ultra High Shear Sanitary Mixer Model HSM-715XSUHD-250 is designed to deliver exceptional dispersion, emulsification, and homogenization at high throughput. Featuring the patented X-Series rotor/stator in type AL-6XN stainless steel, this mixer takes product through the center of the stator and moves it outward through radial channels in the rows of concentric rotor/stator teeth. The combination of high tip speed and extremely close tolerances between the interlocking channels subjects the product to intense shear in every pass.

Designed for continuous operation the HSM-715XSUHD-250 is driven by a 250 hp washdown duty inverter-duty motor and equipped with heavy-duty tapered roller bearings. Its mixing chamber can withstand 150 psig at 250°F and features a stainless steel jacket for heating/cooling. This model is CIP compliant, with the back of the mixing chamber relieved to promote very thorough cleaning around the seal area.

Photo: ROSS

With its ability to produce top-quality dispersions, suspensions and emulsions with uniform size distributions, this versatile and easy to clean mixer is ideal for various industries such as food, cosmetics, pharmaceuticals, chemicals, adhesives, and composites manufacturing.

The HSM-715XSUHD-250 is supplied with a NEMA 12 pre-engineered control panel.

Related Content

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Optimizing Melt-Fed Single-Screw Extruders on Compounding Lines

The main problem with melt-fed extruders that are starve-fed is setting the depth of the metering channel. In this scenario, we describe how this problem was solved.

-

How to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.