Injection Molding: Updated Mold-Filling Analysis Is 30% Faster

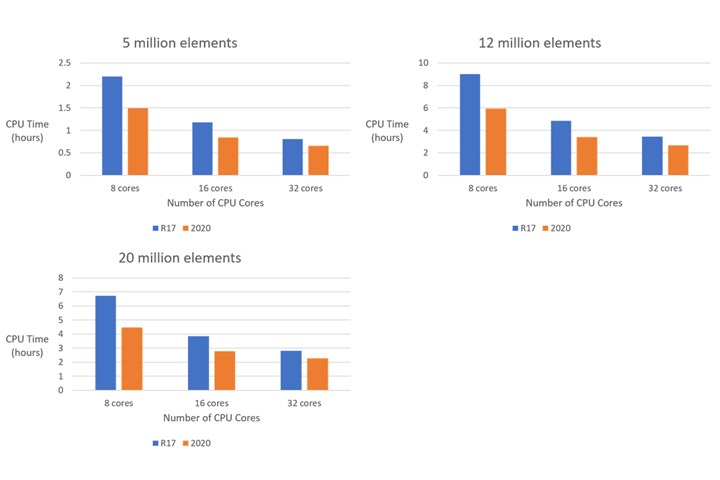

Coretech System of Taiwan says its new Moldex3D 2020 solver averages 30% faster calculations than the preceding R17 version with the same computing hardware.

Share

Read Next

Coretech System of Taiwan says its new Moldex3D 2020 solver averages 30% faster calculations than the preceding R17 version with the same computing hardware. The latest release of the mold analysis software was tested on different high-performance computing platforms with eight, 16 and 32 cores and on mesh models with 5 million, 12 million and 20 million elements. One example is shown here.

Comparison of filling-analysis time between Moldex3D 2020 and R17, using an AMD EPYC 7302 processor.

Related Content

-

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Is There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.