Injection Molding: Optimized Hydraulic Oil Promises Energy Savings

New option for Boy injection machines saves up to 10% or more in energy consumption.

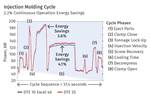

Boy Machines is now optionally equipping its servohydraulic injection machines with an “optimized high-performance hydraulic oil” that is said to offer potential for “considerable” energy savings due to its viscosity profile. As shown in the accompanying graph, the pump motor consumes fewer kW with this oil, dubbed EconFluid, over a range of operating temperatures.

Says Martin Kaiser, Boy’s head of mechanical design in Germany, “Extensive tests with EconFluid showed a significantly lower power consumption of the injection molding machines in comparison with the commonly used hydraulic oils.” For example, power consumption dropped from 1950 W to just 1765 W during a sample cycle. The Boy 35 E reportedly consumes up to 10% less electrical energy with this new oil. Other benefits are said to include consistently lower oil temperature, which saves energy for oil cooling, and longer oil-replacement intervals. With appropriate care, Boy says,EconFluid can be used for up to five years.

For other articles on energy-saving hydraulic oils, see Feb. ’17 and Jan. ’18 Starting Up.

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?