Hot Runners: Two New Control Related Products

Compact operating and display unit and power controller for precise switching of resistive loads launched.

Meusburger has introduced two products related to controls: T7 is intended for the sysTemp and flexotemp controllers, as well as the MPI 02 and MPI 05 components, while the Thypo power controller applies to all industrial segments where precise switching of resistive loads is required.

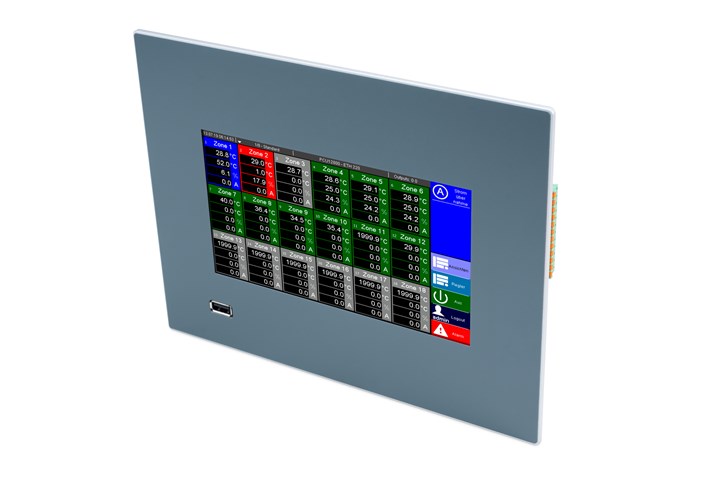

The T7 has a 7-in. touchscreen display for use with various Meusburger controllers. Depending on the controller series, the T7 connects via CAN or Ethernet, granting flexibility in its installation and positioning. Meusburger notes that several controllers, including from different series, can be connected to a T7 at the same time, with the user still able to have an overview at all times. Access to all functions and parameters can be restricted via a three-level user administrator for the control, which supports multiple languages.

The Thypo power controller, meanwhile, is a modular multi loop power controller for switching and controlling heating elements and fields. It can be used in a variety of industries and applications, including plastic molding, welding and film extrusion.

Described as robust and compact, once mounted, the controller is installed by connecting the supply voltage and heaters and assigning heating outputs. Since there are three TP output modules in different power levels, the multi loop power controller can adapt to different applications. A Thypo system can be made up of a maximum of 63 TP output modules, with up to 1512 outlets rated at 1.84 kW per outlet. Because of this, the system can control very large heating fields while needing very little space. With a maximum output of 7.6 kW per outlet, 567 outlets are available per system.

The controller communicates via Profinet IO, Modbus TCP/IP or CANopen. Further interfaces such as EtherCAT or Powerlink will soon be available, according to Meusburger, so Thypo can be used with virtually any make of controller.

The controller has detailed diagnostic functions to solve the errors quickly, and by using reaction-free current measurement, it is possible to quickly detect defective heaters caused by a tripped fuse or by one of the main voltages or frequencies ranging outside the tolerance. Current measurement to compensate for mains voltage fluctuations is standard.

Diagnostic data are transferred to the central system control, and by using the web interface, processors can access the information remotely. Thypo can also be used as an output module for heaters in the flexotemp controller series (PCU and PCU PNIO), as an alternative to use on a controller.

The T7 has a 7-in. touchscreen display for use with various Meusburger controllers.

Related Content

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

How to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

-

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.