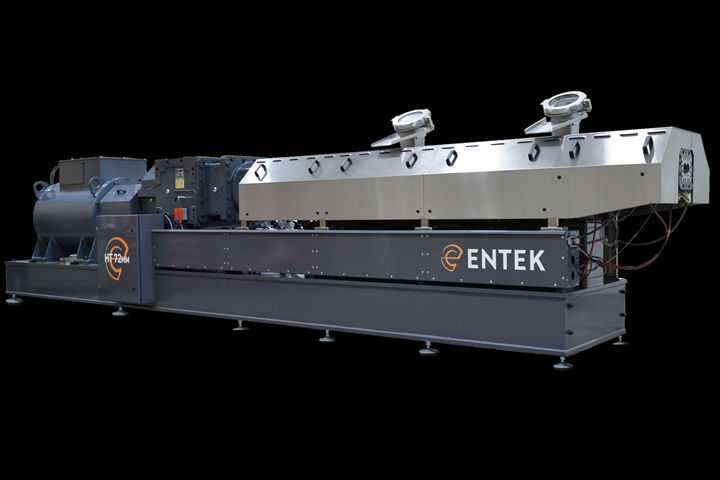

High-Torque Twin Takes Aim at High-Volume Operations

72-mm machine—first in a series—targets high-output commodity and masterbatch compounding applications.

ENTEK Extruders will be distributing literature at the upcoming a series of new products aimed at compounders, including a 72-mm co-rotating twin-screw that is the first in ENTEK’S HT (high-torque) series.

According to the company, the new extruder reportedly delivers the industry’s highest free volume of 1.61 Do/Di at 18 Nm/cm3 torque density, and—depending on the formulation and other factors—can operate at rates up to 10,000 lb/hr.

Photo: Entek Extruders

The target markets, not surprisingly, are high-output commodity and masterbatch compounding, an area that ENTEK previously has not served. In these applications, compounders typically run medium-to-large batch production sizes, and high production rates are particularly critical. And they typically run on a 24/7/365 basis. The machine features an oversized motor and is also said to be well suited for other applications that are torque or power limited.

Related Content

-

Strategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

A Purge Solution for the Blow Molding and Compounding Industries

New commercial purge compounds for new industries from Chem-Trend.