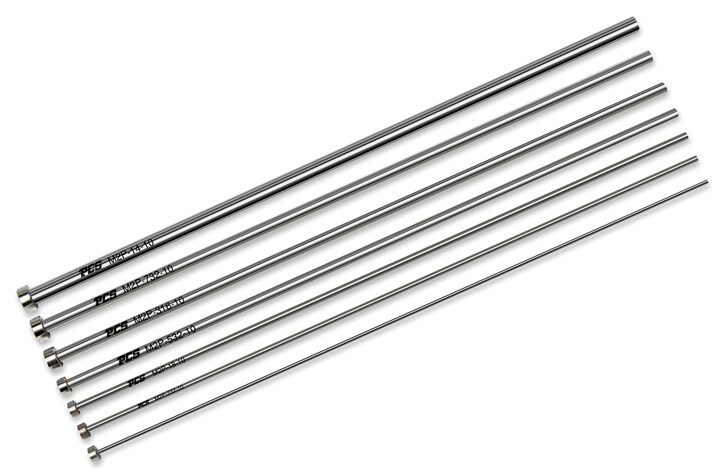

High-Speed Steel Ejector Pins

PCS Company’s new M-2 ejector pins use steel with high carbon content for greater wear resistance.

PCS Company’s new M-2 Ejector Pins are made of high-speed steel, which gives them higher wear resistance and better machineability. Pin diameters range from 1/32 through 1/4 in. with lengths of 6 and 10 in. PCS says the pins’ diameters are precisely ground to provide dimensional stability and superior surface finish quality for ejected parts.

PCS says the M-2 ejector pins target customers who, increasingly, require the pins’ unique specifications for their particular molding applications and tool designs. Additional features of the M-2 ejector pins include through hardening of 60 to 63 Rockwell C, and diameter tolerances held within 0.0003 in. PCS says the pins eliminate chipping from form work and can be used as an ejector pin or a core pin.

PCS Company’s M-2 ejector pins have diameters ranging from 1/32 to 1/4 in.

Photo Credit: PCS Company

Related Content

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

-

How To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.