High-Heat, Flame-Retardant LCP for Electrical Vehicles

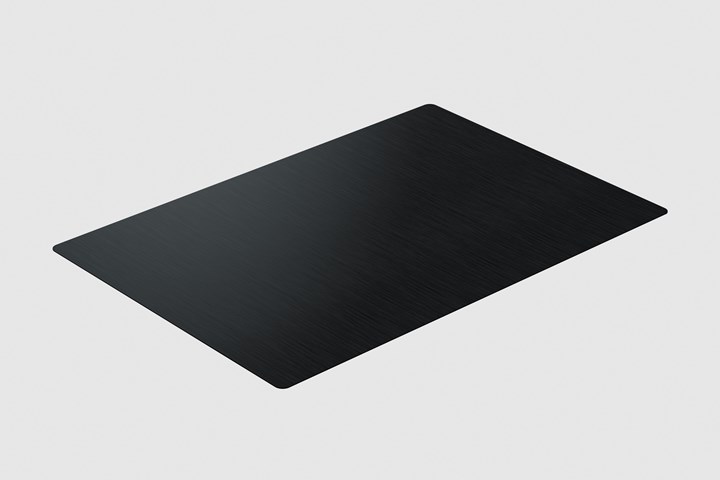

Solvay’s Xydar LCP G-330 HH is designed for high-heat EV battery module insulation.

The latest liquid crystal polymer added to the Xydar LCP portfolio from Solvay is a high-heat, flame-retardant grade which is designed to meet critical safety demands in electric vehicle battery components. Xydar LCP G-330 HH reportedly increases passengers’ safety in the event of a battery thermal runaway. It is said to address challenging thermal and insulation requirements and is targeted particularly at battery module plates of EV models operating with higher voltage systems.

LCP G-330 HH is a glass-filled LCP for injection molding capable of retaining its electrical insulation upon exposure to 752°F for 30 minutes. Xydar LCP is an inherently flame-retardant polymer, without the use of halogen or bromine additives. It also boasts exceptional flowability and helps battery designers achieve thinner parts than possible with incumbent battery module insulation materials, such as PC resins or aerogels. It has been successfully tested with plates molded in typical dimensions of 100 x 150 x 0.5 mm.

Xydar LCP has a proven fit in many electrical and electronic applications. Besides automotive lighting components, sensors, solenoids and connectors, advanced examples in e-mobility include thin-wall slot liners used in the rotor design of an electric drive traction motor. LCP G-330 HH extends the portfolio of Solvay’s battery solutions, which also includes Solef PVDF for binders and separators, Ryton PPS for coolant line connectors and vents, and Amodel PPA for connectors and busbars.

Related Content

-

Prices Up for PE, PP, PS, Flat for PVC, PET

Trajectory is generally flat-to-down for all commodity resins.

-

Prices of All Five Commodity Plastics On the Way Up

Despite earlier anticipated rollover in prices for most of the volume commodity resins, prices were generally on the way up for all going into the third month of first quarter.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.