Fakuma 2023: 3D-Printed Manifold Eliminates Dead Spots Behind Valve Pins

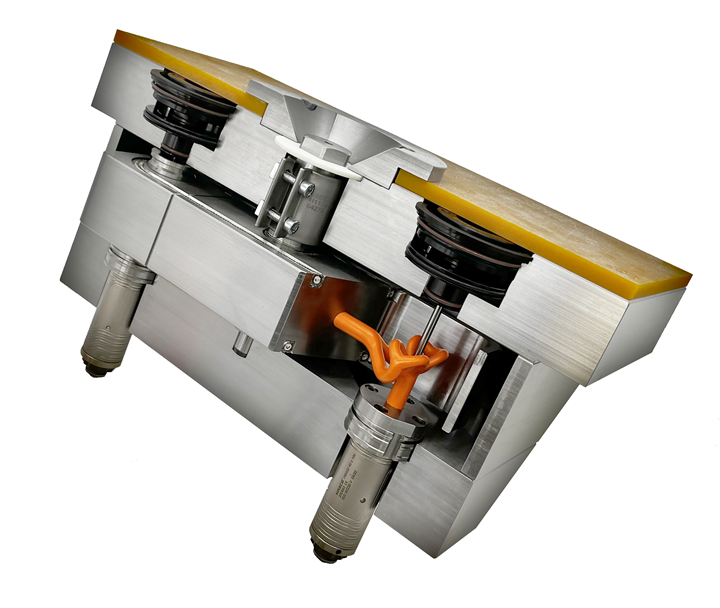

Hasco’s new Streamrunner Shadowfree 3D-printed hot runner manifold is said to eliminate areas of poor flow behind valve pins.

At Fakuma 2023, Hasco will introduce its new 3D-printed hot runner system manifold concept — Streamrunner Shadowfree — which it says will eliminate “shadow formations” behind valve pins or areas of poor flow where material can collect and degrade.

In traditional systems, areas of poor flow in the hotrunner can cause flow disruptions around the valve pin. These “shadows” can lead to plastic degradation and challenging color changes. Streamrunner Shadowfree divides the material flow into streamlined channels, reuniting them where the valve pin enters the melt channel. Hasco says testing has demonstrated the ability to achieve rapid black-to-white material transitions in just 25 cycles.

In addition to eliminating dead spots, Hasco says the Streamruner Shadowfree provides gentle material flow and a marked reduction in pressure losses, as well as smoother processing of heat-sensitive resins.

Hasco introduced the 3D-printed Streamrunner hot runner manifold at K 2019.

Hasco’s Streamrunner Shadowfree hot runner uses additive manufacturing to create unique flow channel geometries. Photo Credit: Hasco

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.