Reciprocating Head Enables Profile-Shape Changes 'On the Fly'

NPE2024: Device eliminates the need to change tools to accommodate different profile shapes and eliminates assembly of the finished profile.

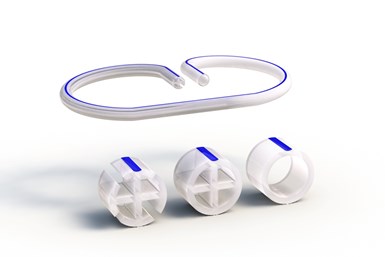

On the new reciprocating head developed by Guill Tool, the typical tip and die assembly is replaced with a linear reciprocating assembly that changes the tube’s profile on the fly within a given length. This process is repeated throughout a single extrusion run without interruptions. As a result, only one extrusion run is needed to produce a finished product, as opposed to multiple runs requiring tooling changes and manual assembly operation to connect different tubing shapes. Guill’s new reciprocating head also eliminates in-process inventory.

Source: Guill

This means there is no need for storage of various tubing shapes and connectors needed for assembly, fulfillment of orders and replenishment of finished goods.

Moreover, the reciprocating head eliminates a connecting piece, enables JIT production and products made-to-order, and reduces total run time from receiving the order to shipping, according to Guill.

Related Content

-

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.

-

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.