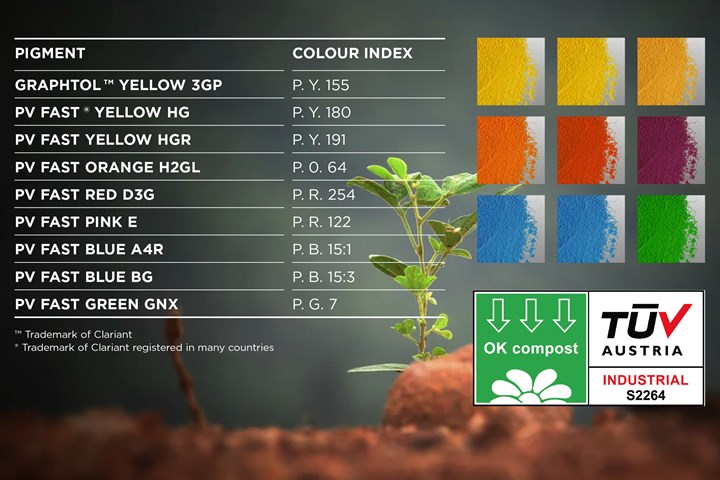

Expanded Portfolio of Pigments Certified OK Compost Industrial

Clariant’s Pigments unit has added nine new pigments that meet the EU’s standard for compostable plastics products.

Nine selected pigments from the PV Fast and Graphtol product lines of Clariant’s pigments 大象传媒 unit, now feature the label OK Compost Industrial that fully meet the requirements of the European Union EN 13432: 2000 standard when not used above the maximum concentration in the final application. The company sees this representing a significant contribution to the growth in compostable plastic articles.

The coloration of biodegradable plastics requires the pigments to meet certain characteristics in order to be considered compostable. For processing through organic recovery facilities, this requires a low heavy metal and fluorine content, and no ecotoxicity towards plants. The PV Fast and Graphtol range of pigment powders are high performance organic pigments. Both product ranges are used in various applications in the consumer goods sector, such as sensitive food-contact packaging, plastics tableware/dishware or toys.

Said Clariant’s technical marketing manager for plastics Andreas Buder,“We are proud of this development that is part of our strategy to offer solutions for more sustainable packaging and to strengthen our product portfolio. This certification allows our customers to use bright colors in their biodegradable products, since they are suitable for industrial composting.”

Related Content

-

Polymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

What are the basic building blocks of plastics and how do they affect the processing of that material and its potential applications in the real world? Meet the repeat unit.

-

Let's Take a Journey into the World of Molding Thermosets – Part 1

There are many fundamental differences between thermosets and thermoplastics, from the way raw materials are furnished to the molder and the process in which parts are molded.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.