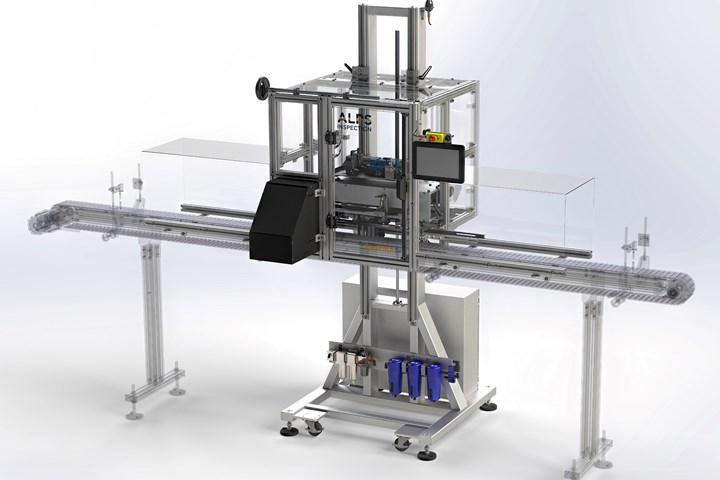

Dual-Head Leak Tester Is Fast & Compact

Test small bottles at up 250 bpm within only 36 in. of conveyor space.

(Photo: ALPS)

The new FlexPitch Duo from ALPS Inspection is said to be a “first-of-its-kind dual-head leak-testing system” that allows bottle makers to test 100% of small bottles (3 ml to 1.75 L) in a limited space. The unit has dual independent moving test heads, which occupy the same space for a small footprint. Only 36 in. (914 mm) of free conveyor space is required. That is less than for the company’s four-head leak tester and only slightly larger than the single-head model. No line modification is required; it fits around an existing conveyor.

What’s more, the leak tester is easily moved from line to line. It tests bottles in line, so no transfers are required to and from separate leak-test conveyors. This is said to be especially important for reverse-taper and other hand-to-handle bottles that can tip over if held at an accumulating station before leak testing.

Features also include a color touchscreen and 24-hr service support. The controller has remote connectivity for software updates and can store test data and produce reports including trend graphs.

The moving test heads are designed to keep up with the increasing speed of blow molding machines—from 75 bottles/min for larger containers up to 250 bpm for smaller vials, eye droppers, single-serve liquor bottles etc. Containers entering the machine are detected with a photocell and tracked by an encoder as they move on the conveyor throughout the test cycle. When a bottle arrives under a test head, a test probe seals the top of the container and follows the container as it is tested under low pressure. The probe retracts after the test and returns to the start position. Bottles failing the leak test are automatically diverted to a reject chute.

Related Content

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

-

PolyJohn Turns to Blow Molding, Doubles Its Productivity

Leading maker of portable sanitation products knew thermoforming, sheet extrusion, rotomolding and injection molding. Then it found the missing link to higher productivity and new markets: blow molding.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.