DME to Unveil New Units, Products at K 2022

DME will highlight new products from three newly organized 大象传媒 groups: DME Thermal Management Solutions, DME Modular Mold Systems and DME Digital IoT Controls.

At K 2022, injection mold technology supplier DME will showcase new offerings from distinct 大象传媒 groups organized around temperature control, modular mold components and Industry 4.0 controls. In temperature control, DME Thermal Management will introduce iControl Insulation. This encapsulated and insulated hot runner system reduces energy consumption and boosts the productivity by lowering heat loss from the manifold and nozzles.

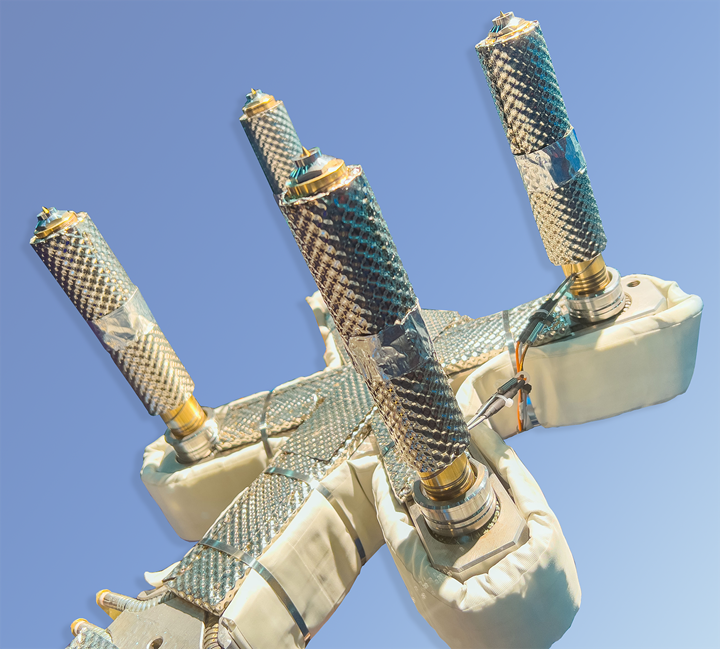

DME iControl insulation prevents heat loss from hot runner nozzles and manifolds.

Photo Credit: DME

DME Variotherm supports the design of aesthetic plastic parts allowing matte and gloss finishes to be produced by the molding process itself. This heating and cooling system cycles from 20 to 200°C incredibly quickly, according to DME. In addition to energy savings, this can lower carbon footprint and increase overall efficiency by eliminating painting steps.

DME says Variotherm optimizes control via time and temperature monitoring, with the ability for integrated trend monitoring. Typical applications are high gloss or matte textured, interior vehicle panels, which are molded in cycle times of 30 to 60 seconds and reportedly free of sink marks or welding lines.

From DME Modular Mold System comes the SmartONE Hot Runner. The company describes this as a cost effective modular hot runner, available in both open and valve gate models. It has been standardized on a global platform to ease aftermarket service. DME 3D modular mold concepts are fabricated using additive manufacturing enabling new products to be developed faster.

In addition the company will showcase the EZ-Stack ball screw device; Accualign Lifters, with conformal cooling; and S-Core collapsible cores, with improved cooling.

DME Digital IoT Controls will highlight SmartMold mold monitoring, as well as M2+ Hot Runner Controllers, which offer valve gate and servo control. The DME Connect QR system, meanwhile, allows end users to connect to the internet for data about molded parts.

Related Content

-

Netstal To Introduce Next-Generation All-Electric Elion Injection Molding Machines at K 2025

Netstal will introduce the Elion MED in Düsseldorf with a smaller footprint and greater energy efficiency.

-

Women in Plastics Event Debuts at K 2025 Oct. 12 in Düsseldorf

The “Women in Plastics” event will debut at K 2025 on Oct. 12 at 4 p.m., where participants will have the opportunity to learn from others’ experiences and build valuable networks.

-

All-Electric Injection Machines Enable More Sustainable, Energy-Efficient Processing

Stork’s all-electric injection molding machines include a breaking energy feedback system in which recovered energy can be fed back into the customer energy grid.