Distinguishing HDPE from LDPE at the Blink of an Eye/Push of a Button

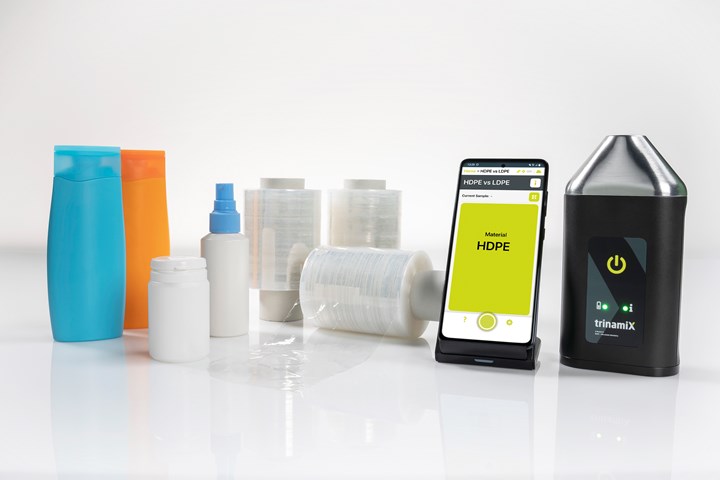

BASF’s trinamiX adds new PE application for plastic sorting to its mobile NIR spectroscopy solution.

The ability to distinguish between HDPE and LDPE at the push of a button is the latest application for plastic sorting added to the Mobile NIR Spectroscopy Solution from Germany-based trinamiX GmbH. Founded in 2015 as a wholly-owned subsidiary of BASF, Germany-based (trinamixsensing.com) develops and sells cutting-edge 3D vision and infrared sensing solutions for use in both consumer electronics devices and industrial designs.

BASF sources noted that in view of rising prices of polyethylene, the production of single-grade PE recyclates has become extremely attractive in recent months. By launching two applications for its mobile NIR spectroscopy solution, trinamiX is improving on-the-spot sorting of the sought-after plastic. In addition to quickly distinguishing between HDPE and LDPE, the ratio of PE to PP in mixed plastics reportedly can be precisely determined as easy as pushing a button. Thanks to the flexibility of a handy measuring device, the process for obtaining high-quality PE and PE/PP recyclates is now significantly enhanced.

Polyethylene is the most widely produced plastic in the world and the most popular thermoplastic for foils and packaging. Depending on its density, PE can be divided into HDPE (high-density polyethylene) and LDPE (low-density polyethylene). While the similar characteristics of HDPE and LDPE lead to overlaps in their respective applications, differences in their mechanical properties have an impact on their processing and the subsequent recycling process. In the context of recycling, a separation by type has a favorable effect on the quality of the recyclate.

Also, trinamiX’s solution now provides valuable insights when it comes to the recovery of mixed plastics made of PE and PP. By determining the percentage ratio in PE/PP mixed plastics, recyclers can sort incoming commodity streams with greater precision. This way, the different specifications and quality requirements of the recyclates can be attained more accurately.

"The current undersupply in the PE market and the associated price increases we’re observing on our digital trade platform are opening up new opportunities for recycling companies," explains Florian Hüter, Head of Sales at cirplus, the global marketplace for circular plastics. "trinamiX’s applications make their sorting process for the different commodity streams fast and easy, thereby increasing their recycling capacities for PE recyclates."

Since the introduction of the plastic sorting application last year, trinamiX’s solution has already empowered users with the rapid identification of common plastics, including the classic polyolefins PE and PP. Since then, trinamiX has been continuously expanding its broad offering in close cooperation with customers. As recently reported, the introduction of an application that enables the quick differentiation of the engineering plastics nylons 6 and 66.

Related Content

-

The Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

-

Prices Flat-to-Down for All Volume Resins

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

-

Fundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.