Cooling Added to Compact Slide

NPE2024: CUMSA adds cooling to the Compact Slides (CS) line launched last year.

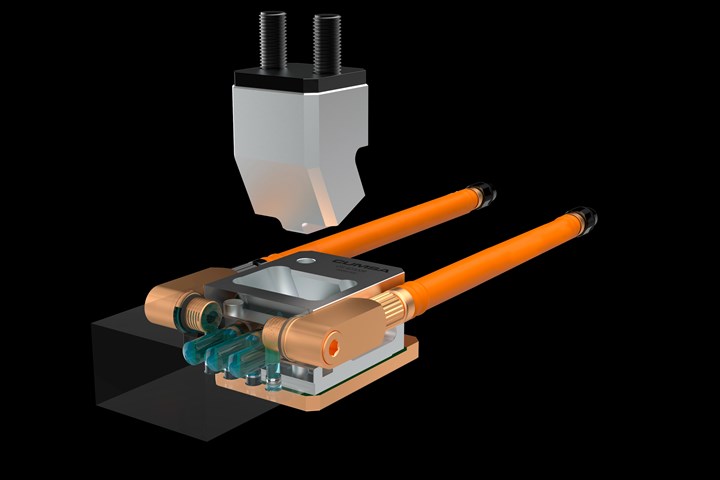

CUMSA is adding a cooling system to its Compact Slides (CS) with a floating insert, helping molders optimize the cooling process, lower cycle times, decrease energy consumption and improve plastic part quality. This cooling system design, combined with the insert, eliminates the need for a high-precision pocket. Available in three standard sizes — CR42, CR52 and CR62 — the cooled, compact slides feature an insert with predrilled holes to ease finishing the cooling circuit once the insert detail is machined. The three sizes have three, four and five predrilled holes, respectively.

Helping remove heat during molding, these cooling systems target difficult-to-cool areas in the CS line. The inserts have a 1/8 GAS-threaded hole on each side to connect the cooling hoses, which are sold separately, directly to the waterlines. The compact slides have strokes ranging from 9 to 22 mm, with ±0.05 mm horizontal movement to ease installation.

Predrilled holes ease finishing of the cooling circuit for CUMSA’s CS floating insert. Source: CUMSA

Related Content

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

How to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.