Conformal Cooled Sprue Bushings Line Expanded

PCS Company has added a 3/4-in radius for the U and B Series bushings options.

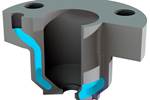

PCS Company has expanded its Conformal Cooled Sprue Bushings product line, which is designed to reduce cycle times for injection molders by providing for faster cooling of plastic sprues. Provided as direct retrofits to the common U (3/4-in diameter) and B (1-in diameter) series sprue bushings, the products are available in 8 (Model U) and 12 (Model B) standard sizes. PCS can also provide custom sized bushings for specific applications. These bushings are constructed of stainless steel for corrosion resistance and longevity.

Previously available in 1/2-in radius sizes, PCS has added the 3/4-in radius size options for both the U and B Series bushings. While cold sprue bushings often use straight-line cooling channels and require extended cooling times for the hot plastic to solidify, conformally cooled bushings use curved channels to improve cooling of the sprue, which PCS says reduces cycle times, increases efficiency, and provides better process control.

For easier ordering, PCS has updated its catalog pages with more information and updated CAD drawings. The company says it has also lowered prices.

PCS has added new standard sizes for its line of conformall cooled sprue bushings.

Photo Credit: PCS Company

Related Content

-

How to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.