Compounding: Closed-Loop System for Coex Film Reclaim

New system permits reclaim of multi-layer production scrap at rates up to 100%.

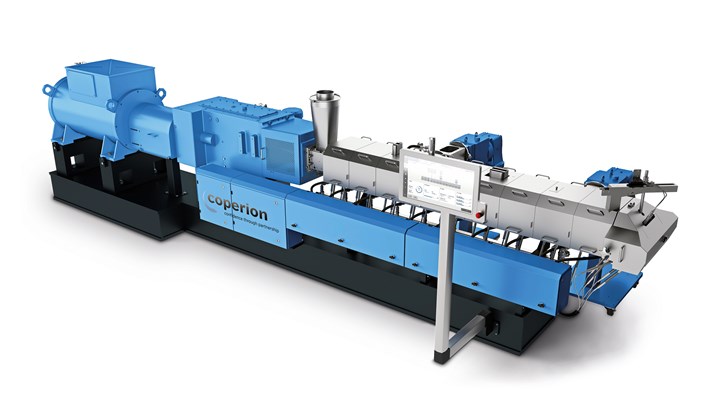

Coperion has developed a closed-loop system for recycling post-industrial multi-layer film, a recovery process that historically has been challenging and complicated. The recycling system consists of bulk material handling equipment, a Coperion K-Tron feeding system and Coperion’s ZSK Mc18 twin screw extruder.

In the Coperion setup, multi-layer production scrap would first be shredded, then fed into the ZSK extruder via pneumatic conveying and highly accurate feeding from Coperion K-Tron. In the co-rotating ZSK Mc18 twin screw extruder, material is homogenized and devolatilized. Coperion says the extruder is designed to “gently” and thoroughly mix the material even at very high throughput rates, generating consistently high product quality.

Following homogenization, the recycled material is added back into the production process at rates up to 100%.

Related Content

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

-

Evolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

-

Coinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.