Compact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

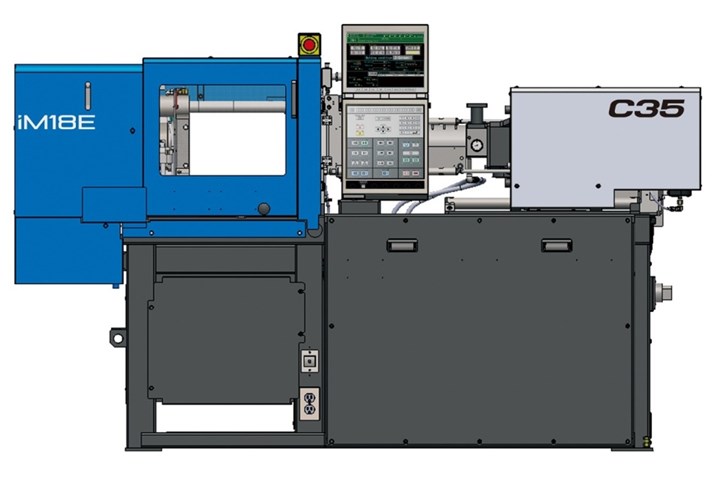

Sumitomo Heavy Industries Ltd. (SHI) of Japan launched the 20-ton iM18E compact hybrid injection molding machine with a footprint of just 88 by 30 in. on Jan. 31, 2023. Designed especially for molding connectors, precision gears and other electronic parts, the iM18E has a maximum injection speed of 600 mm/sec. A company spokesperson told Plastics Technology that at this time the machine will only be sold in Japan and other Asian markets.

SHI says the iM18E occupies approximately 21% less space than the company’s equivalent model SE18DUZ. Floor space required for the iM18E is greatly reduced thanks to a redesigned injection unit and a machine frame that allows peripheral equipment to be housed under the machine.

The iM18E’s features a hydraulic direct-pressure clamp, with an electric plasticizing unit featuring a low-inertia servomotor. Controlled by the ISCII direct-drive system, SHI says the iM18E reduces shot-to-shot weight variation to about one-third of that of an equivalent hydraulic machine. The hybrid design reportedly reduces power consumption by 50% in comparison with the equivalent hydraulic machines.

The 20-ton iM18E compact hybrid injection molding machine occupies approximately 21% less space than the company’s equivalent press.

Photo Credit: Sumitomo Heavy Industries Ltd.

Related Content

-

Use These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

-

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.