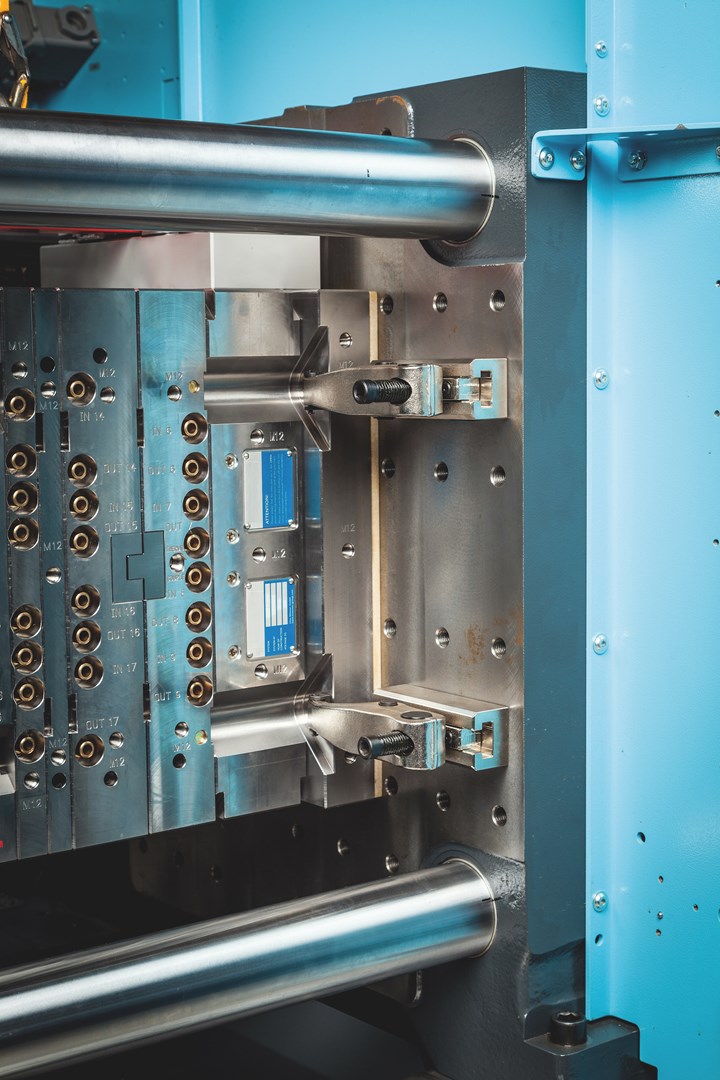

Clamps Allow Faster Mold Changes

Mouldpro says its Power Sliding Clamp can accommodate a range of different mold back-plate sizes and thicknesses.

Mouldpro ApS (Ballerup, Denmark), which is distributed in North America by Globeius, has introduced the Power Sliding Clamp for faster mold changes. The clamps can adapt to a range of different mold back-plate sizes and thicknesses, with four clamp sizes are available. The sizes include the SC-100 (3500 lb clamp force), SC-200 (4400 lb clamp force), SC-250 (5500 lb clamp force), and the SC-300 (12,100 lb clamp force).

These clamps can be used in threaded or t-slot platens and are designed to slide by virtue of an integral t-slot. This feature allows it to be fixed in the best position for clamping, according to Mouldpro, with an adjustable bolt suited for different clamp heights. Able to work with Quick Mold Change (QMC) setups, these clamps feature a nickel-plated finish for corrosion and wear resistance. Globeius has the clamps in stock and ready for delivery throughout North America from its warehouse in Miami.

Mouldpro has introduced the Power Sliding Clamp with four sizes available.

Photo Credit: Globeius

Related Content

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

-

How To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.