Brüggeman & Grafe Develop Color-Stable eOrange Masterbatches for Molded & Extruded E-Mobility Nylon Compounds

What are said to be color-stable and cost-effectively processed eOrange nylon masterbatches for molded and extruded nylon components uses in E-mobility, have been jointly developed by Germany’s additives supplier Brüggeman and compounder Grafe.

What are said to be color-stable and cost-effectively processed eOrange nylon masterbatches for molded and extruded nylon components uses in E-mobility, have been jointly developed by Germany’s additives supplier Brüggeman and compounder

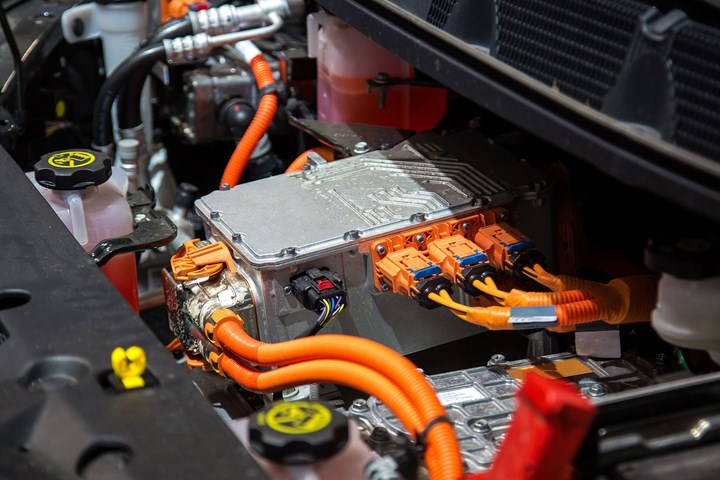

The striking pastel orange RAL2003 is increasingly being used to identify plastic-sheathed, high-voltage, current-carrying components in E-mobility to warn of the dangers associated with this new technology. eOrange is a color masterbatch for nylons, which even after 1,000 hours’ service at 130 C/266 F, reportedly still retain their warning effect without darkening. In comparison with preformulated compounds, eOrange offers processors considerable flexibility in meeting specific requirements and at the same time optimizes material consumption.

Named PA-Tekolen, the new eOrange masterbatch, now offered by Graffe, can be used for nylons 6 and 66, and glass fiber-filled and flame-retardant nylons while maintaining mechanical material properties. Its flexible rate of addition is said to distinctly better control over this “critical” color than do commercially available compounds. Its performance is based on a combination of highly thermally stable dyes with special heat stabilizers developed by Brüggemann for nylons. Possible applications include high-voltage connectors, insulation for high-voltage cables, cable conduits, charging sockets or fasteners for electric vehicles, while wiring harness clips are already in series production. Formulations for other polymers are available on request.

Said Grafe’s head of sales Lars Tonnecke, who is playing a key role in the development of Grafe eOrange, “In line with current trends, we, like our long-standing partner Brüggemann, have been receiving increasing numbers of inquiries from the E-mobility sector for some time now. And that's why we started work on this joint project in late 2019. Brüggemann’s high-performance heat stabilizers and its know-how protect the polymers from unwanted changes, while Grafe contributes its expertise in coloring and upgrading plastics. Customer benefits include ease of use of the masterbatches when tailoring individual applications and associated flexibility and cost advantages.”

Grafe is the first point of contact for the use and distribution of eOrange. A specialist in high-performance heat stabilizers and other functional additives for nylons, including flow improvers and light stabilizers, Brüggemann can also provide advisory support and supply small volumes for the custom development of specific applications.

Related Content

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.