Blow Molding: New Packaging Machine Concept Previewed at K 2019

A sleek new look from Bekum, plus new extruder and controller and quick mold change.

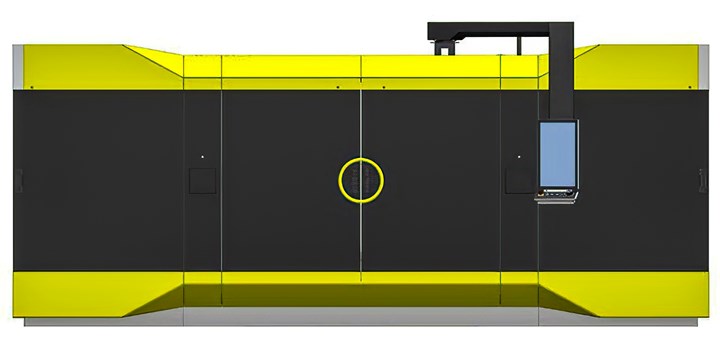

While many exhibitors at the K 2019 show next month in Düsseldorf will show off their latest current products, Bekum will offer a peek at what’s ahead. Its “Concept 808” future packaging machine line offers sleek lines and large safety gates, as well as variable-color LED lights that indicate operating status. They also offer a new generation of high-output extruders that boast high energy efficiency.

Bekum’s Concept 808 features sleek lines, large safety gates, and colored LED status-indicator lights.

The brand-new Bekum Control 8.0 for these shuttle machines offers a 24-in. touchscreen with multi-touch capability and displays of throughput and consumption of power, water and air.

Also featured is optional magnetic clamping for quick change of molds and blow pins. Mold change reportedly takes 15 min without tools or a special mold cart.

Related Content

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

-

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.