Blender Built for Hard-to-Handle Materials

NPE2024: New series targets application using recycled materials. Quick-change feeder also debuts.

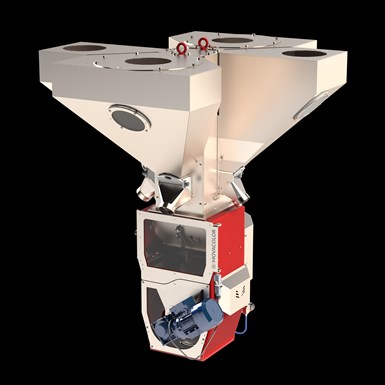

Movacolor has added the 20-recycling series to its MBS blender range, specifically targeting plastics processors working with recycled material in their production processes. This blender is capable of processing hard-to-handle materials such as PCR, flakes and certain regrinds.

The material hopper oscillators ensure optimal flow of the material while the isolated upper body filters vibrations to ensure high dosing accuracy. Optionally, the material hoppers can be equipped with bridge-breakers to prevent material blocking or bridging. Like the regular Movacolor 20-series, this blender is characterized by its intuitive controller, robust design, and absence of mechanical parts and cables in the material hoppers. This enables easy accessibility for cleaning, material changes and other routine tasks.

The MBS Blender 20-recycling series (photo) can be upgraded to a MHBS Hybrid blending system for optimal control over critical or expensive additives. This hybrid system combines gravimetric blending and dosing in one integrated system.

Movacolor is also taking the wraps off the MDS Volumetric Feeder, developed for plastics manufacturers that require a high-performing dosing unit at a cost-effective price. The unit has a new intuitive touchscreen in combination with the latest control software technology, which Movacolor says make it unique.

Thanks to an intuitive design, this dosing solution enables a swift 60-second cleaning and material change through a discharge valve and easy motor, hopper and dosing tool release. As a result, downtime and changeover time can be minimized.

The MDS Volumetric Feeder is part of Movacolor's modular dosing concept and can be combined with other units, as well as specifically tailored to fit the requirements of different production processes.

Related Content

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

-

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.