Bio-based Elastomer for Biopharmacuetical Tubing

Avient introduced its Versaflex elastomer formulated with bio-derived content.

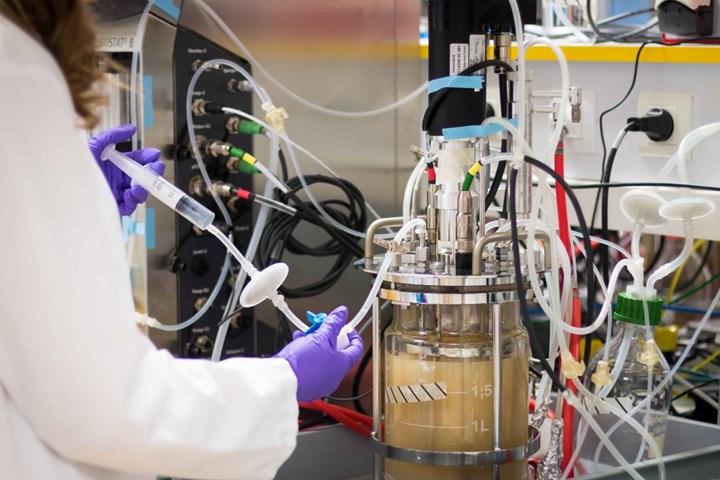

Avient Corporation announced the availability of Versaflex HC BIO, thermoplastic elastomer (TPE) with bio-based content. Developed as an alternative for biopharmaceutical tubing, the initial Versaflex HC BIO BT218 grade is formulated with nearly 40% first-generation biomass content, resulting in a lower carbon footprint than traditional options.

Avient new product is aimed at tubing for pharmacuetical applications.

Photo Credit: Avient Corporation

The 71 Shore A formulation provides critical application performance such as weldability, kink resistance, and tensile strength comparable to leading medical tubing materials, including silicone and standard TPEs. The bio-derived grade offers greenhouse gas emissions at 2.35 kg CO2e / kg product, a nearly 25 percent lower cradle-to-gate product carbon footprint than Avient’s standard Versaflex HC BT218 grade. Avient’s product carbon footprint calculation method follows the ISO 14067:2018 standard and is certified by TUV Rheinland, an independent testing service company.

Certified for USP Class VI and ISO 10993, the new Versaflex HC BIO BT218 grade is manufactured in the United States with global commercial availability.

Related Content

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.