Biobased, High-Performance Aliphatic Nylon 46

DSM’s Stanyl B-MB 100% biobased version of the company’s flagship Stanyl 46 and said to be an ‘industry-first launch’ of a biobased high-temperature nylon.

A new 100% biobased content high-performance aliphatic nylon 46 has been added to the Stanyl nylon 46 portfolio of DSM Engineering Materials. Designated Stanyl B-MB (Biobased Mass Balanced), this more sustainable version of the company’s flagship material, reportedly offers the same high performance offered by its virgin counterpart. Its excellent high-temperature mechanics (melting temperature of 554 F/290 C), superior flow and processing, and distinguished wear and friction resistance make it ideal for high-temperature applications in automotive, electronics, electrical, and consumer goods industries, such as USB connectors, automotive and industrial actuator gears, powertrain timing chains, bearing cages, and food contact conveyors.

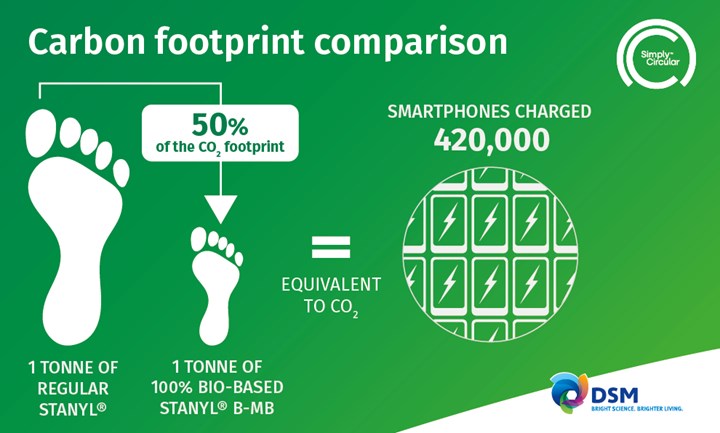

Using the maximum possible levels of biomass-waste feedstock, it enables DSM to halve the carbon footprint of this product line and, in turn, of the Stanyl B-MB-based products of its customers. This ‘industry-first launch’ of a 100% biobased high-temperature nylon underlines the company’s ongoing commitment to helping customers fulfil their sustainability ambitions by making planet-positive choices and supporting the transition to a circular and biobased economy.

Global production of biobased products roughly doubled between 2015 and 2020, but the materials industry urgently needs to accelerate the shift to sustainable feedstocks, according to DSM, which has committed to providing bio- and/or recycled-based alternatives for its entire portfolio by 2030. Stanyl B-MB is a fully ISCC+-certified massbalancing solution, and has been shown to deliver exactly the same characteristics, performance, and quality as conventional Stanyl, yet its production now generates a carbon footprint up to 50% lower than the fossil-based original. In practice, this means a 3.3-ton CO2 reduction per ton produced – equivalent to charging 420,000 smartphones, according to DSM.

Related Content

-

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

How to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.