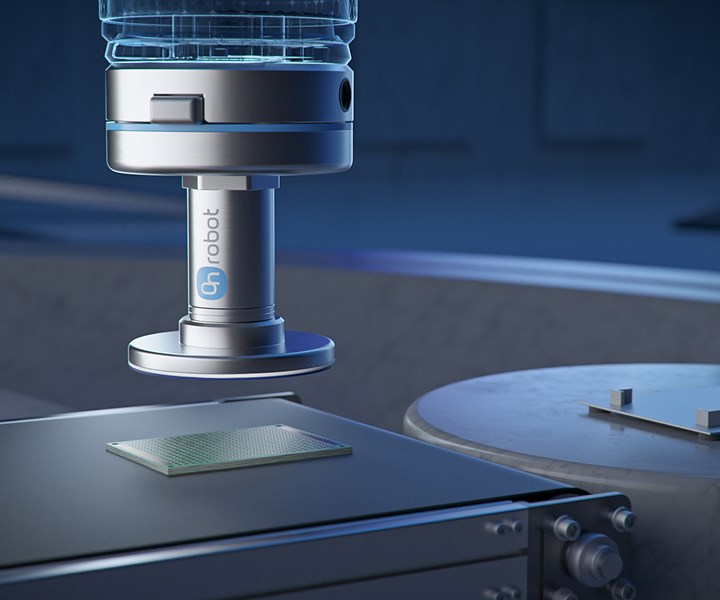

Automation: Smaller Non-Marking Gripper For Smooth, Shiny or Perforated Surfaces

OnRobot’s gripper mirrors the microstructure of a gecko lizard’s feet.

, the Danish maker of end-of-arm tooling for collaborative robots (cobots), came out with a smaller version of its novel Gecko adhesive gripper for smooth, shiny or perforated surfaces. The Gecko gripper utilizes millions of micro-scale fibrillar stalks that adhere to surfaces by means of van der Waals forces—the same way that gecko lizards are able to climb vertical walls. Because this silicone-based technology doesn’t mark even high-shine surfaces, OnRobot claims, it eliminates the need for a cleaning step in some manufacturing processes. And the Gecko grip also can grip even perforated workpieces, like printed circuit boards, aluminum mesh, or head gaskets. No wires or air supply are required.

OnRobot’s Smaller single-pad Gecko gripper can handle perforated parts like circuit boards and won’t mark shiny parts.

The new Gecko SP (single pad) gripper brings this capability to smaller applications and lighter payloads. It comes in three sizes for payloads of 1, 3, and 5 kg, vs. 5.5 to 6.5 kg for the larger, four-pad Gecko gripper. The gripper is said to offer “plug-and-play” compatibility with a wide variety of cobot brands.

Related Content

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

-

'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.