Automation: Predictive Maintenance, Cleanroom Versions & Recycling of Energy Chains

igus reports a number of recent developments in automation components.

In a recent review of new developments in its flexible plastic energy chains, or “e-chain” cable carriers used in robotics and other automation components, highlighted the following:

• The company is now taking back used e-chains for recycling—regardless of the manufacturer. It has collected one to two tons of cables since December.

• For clean rooms, igus launched its first “clean cable system” that can be opened and closed. This e-skin flat modular, flexible sleeve snaps open and closed allows for quick and easy expansion or replacement of the cables in an e-chain. A new e-chain support for this system allows for longer travel than before. In addition, igus has commissioned a new cleanroom lab, certified to ISO Class 1, at its German headquarters.

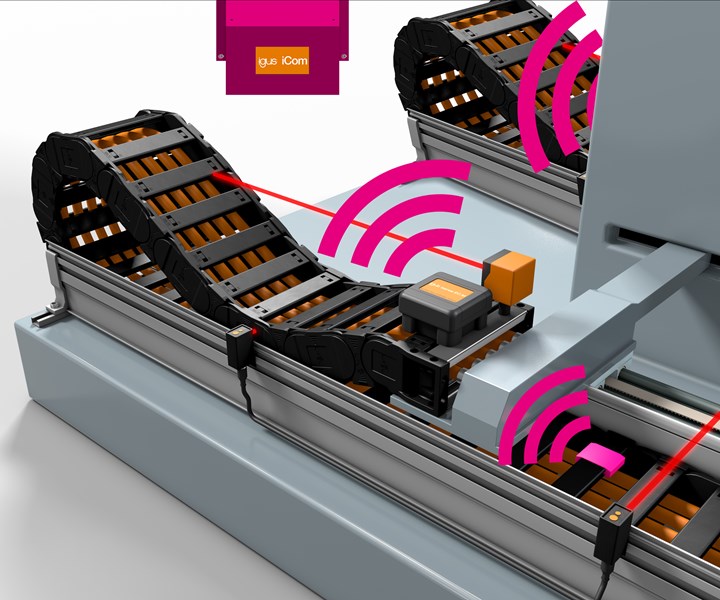

‘Smart’ igus e-chains with condition-monitoring sensors facilitate predictive and preventive maintenance.

• igus has several new products aimed at remote maintenance monitoring (condition monitoring) of energy chains. A new small electronic box connects to all sensors on the e-chain and to a junction box for communication with the customer’s or igus’s servers. An info dashboard presents the maintenance status to the user.

Also new is the ecw wear-detection sensor for e-chains. It’s attached to the e-chain and connects directly to the igus cloud. Cost is around $500. Igus also supplies a new eci wear sensor for “smart bearings.” Non-lubricated bearings with integral wear sensors are now available in five types.

The company’s ecp push-pull force-detection sensor, which previously functioned for chain movements up to 120 meters, is available in a new ecpr version that can travel up to 1000 m or more.

The new ecpp position sensor is being used by one overhead crane supplier to monitor its position. This new device reportedly saves four to six days in crane installation time.

Also new is software for use with the cfd cable condition-monitoring sensor to predict the cable’s lifetime, using artificial intelligence (AI) and machine learning. One customer is using this system to help achieve 50 million cycles for bread-packaging machinery that operates at 120 pieces/min.

Related Content

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

How to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.