Array of Recycling Machinery to Debut at K 2022

EREMA will present several recycling equipment innovations at K Show, live recycling demonstrations, and an exhibit of products made from recycled materials.

has announced a series of new products it will display at K 2022, October 19-26 in Dusseldorf. They include:

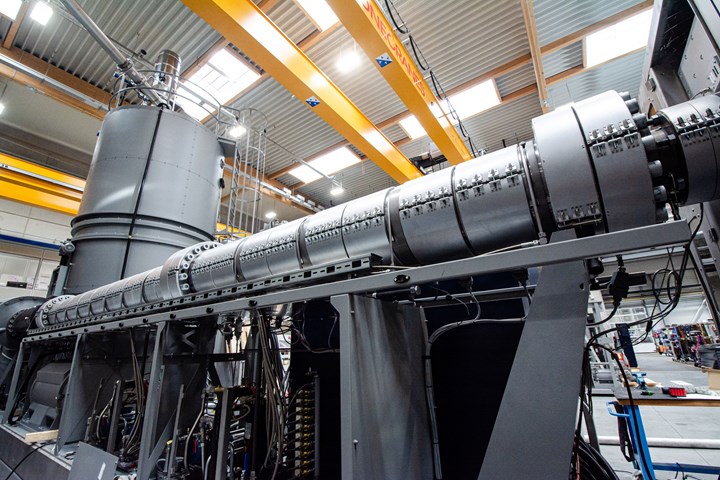

- A larger VACUREMA recycling extruder with advanced plastification technology, able to process up to 13, 227 lb/hr while using 10% less energy. The technology also promises a broader process window and gentler material treatment.

EREMA’s large recycling extruder, the VACUREMA. All photos: EREMA Group GmbH

- EREMA’s entry into chemical recycling, CHEMEREMA, which will focus on optimizing extruder output for downstream chemical recycling.

- A small-footprint extruder for inline trim recycling, the ALPHA XS. ALPHA XS can process up to 110 lb/hr and features air-cooled pelletizing.

- A prefabricated recycling extruder, the READYMAC.

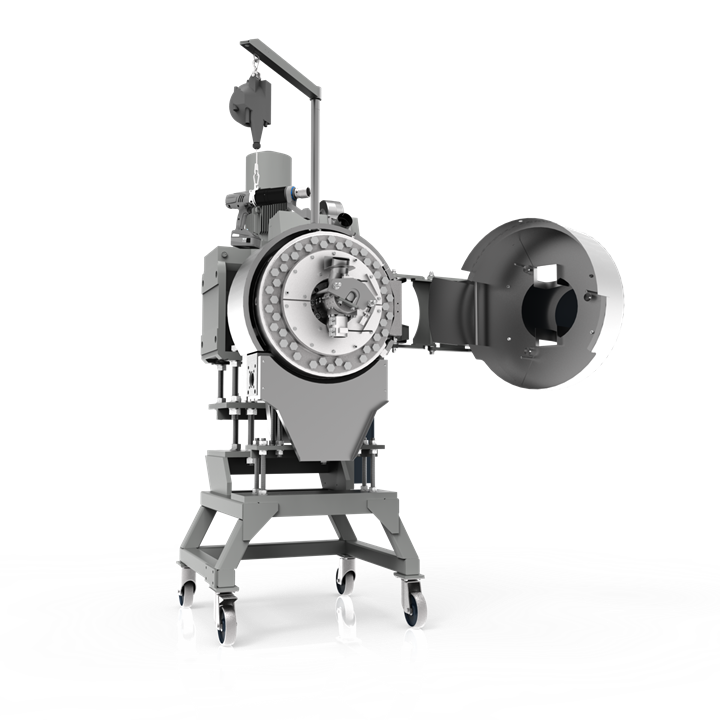

- LaserFilter 406, an extrusion filter with 50% increased area, providing capacity up to 19,840 lb/hr.

The new 2/406 Laserfilter from EREMA Group.

- Industrial-scale deinking to support recycling of printed film.

- PredictOn, new equipment instrumentation and software which will enable predictive maintenance by reporting early changes to critical equipment components. PredictOn will begin with drivetrain monitoring, with other systems to follow.

- BluPort apps for real-time monitoring of machine performance.

EREMA also recently announced an investment in start-up company , a manufacturer of mobile recycling equipment. Plasticpreneur focuses on providing recycling solutions in regions that lack infrastructure for larger equipment.

At the outdoor area of K Show, EREMA will present live recycling demonstrations and an exhibition of products made from recycled materials.

Related Content

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

The Importance of Mass Balance in Chemical Recycling

Approaches to mass balance can dramatically impact calculations of recycled content.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.