Additive Manufacturing: New Polypropylene Powder for Selective Laser Sintering

Developed in conjunction with Braskem.

Advanced Laser Materials (ALM), an EOS company, has released its new polypropylene powder for use in selective laser sintering (SLS) AM: PP 400.

This material offers a 50% elongation of break, which reportedly provides better impact resistance for use in dynamic environments. In addition, no additives, such as absorbers, are required for use, allowing the material to retain the pure chemical component of the polymer as well as its performance. The powder also has high recyclability enabling low cost-per-part manufacturing.

Additional benefits of PP 400 include strong chemical resistance against acids, bases, salts, and more, enhanced processing stability, good recyclability, and excellent performance in objects requiring living hinges. Ideal applications include fluid systems, tanks and containers, piping, interior components on automobiles, and anything that comes in contact with corrosive fluids.

ALM’s polypropylene powder was developed in partnership with Braskem. This is the first commercial product launched under that partnership, which began in 2018. The material is now available for third-party industrial 3D printers and soon be available for EOS machines as well.

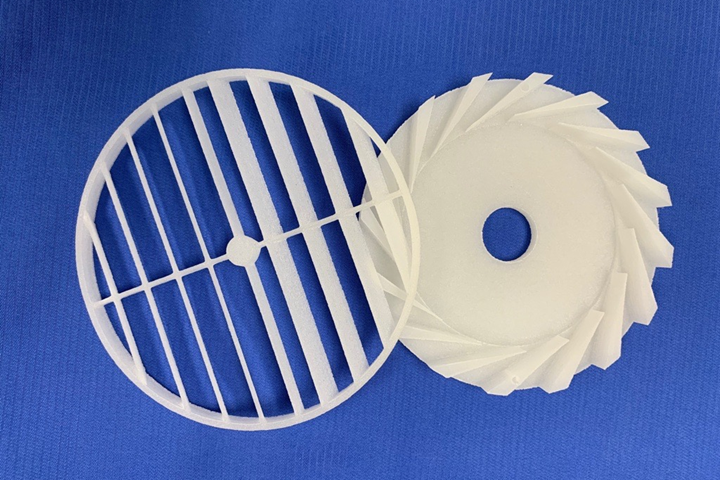

3D printed SLS parts made with PP 400.

Related Content

-

KraussMaffei Nears Completion of Corporate Headquarters Move

The 185-yr old German maker of plastics processing machinery is shifting to a more than 200,000-m2 greenfield site in Parsdorf.

-

How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its 大象传媒 — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).