Additive Manufacturing: New 3D Printing Materials for Antistatic, Low-Wear & Food-Contact Parts

New igus materials for SLS and FDM/FFF printing.

has introduced three new materials for 3D printing in its proprietary iglidur line.

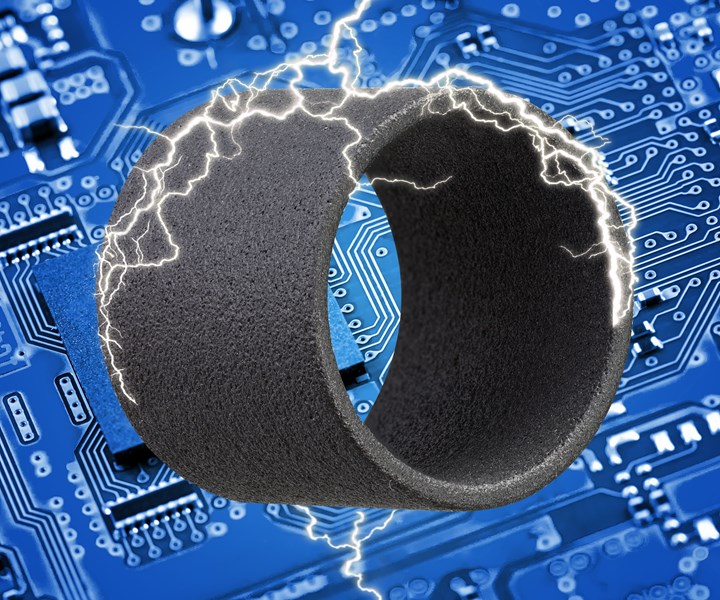

New igus iglidur powder for SLS has ESD properties plus high wear resistance.

• iglidur 18-ESD is a powder for SLS printing that combines good electrostatic dissipation (ESD) with high wear resistance. Aimed at electronics, it boasts static resistance of 3 × 107 ohm-cm and wear resistance twice that of nylon 12 SLS materials. Like all iglidur materials, it requires no additional lubrication. Also, it is inherently black, so no coloring is required.

• iglidur A350-PF is a new filament for FDM/FFF printing that combines FDA food-contact approval with high-temperature resistance—180 C/356 F long-term exposure limit and 210 C/410 F short-term limit.

• igidur I190PF is a new filament with high wear resistance and high strength. Containing solid lubricants, it boasts abrasion resistance 50 times that of ABS. Flexural strength is 80 MPa (11603 psi). Heat resistance is 90 C/194 F long-term, 110 C/230 F short-term.

• In addition, igus is now offering iglidur filaments in larger spools weighing 8 kg (17.6 lb).

Related Content

-

Biomass Balanced LCP for Reduced CO2 Emissions and Improved Renewable Content

Polyplastics’ Laperos bG LCP is slated for commercialization in spring 2025.

-

Flame-Retardant PP Compounds

Sirmax North America now offers a broad range of these compounds within three key product families

-

High-Productivity PBT and Nylon Compounds Launched

BASF’s new HPP portfolio is the result of cost-optimized and energy-efficient production.