Acetal Color Masterbatches for Automotive and More Based on Low-Emission Carriers

Tosaf’s new functional and combination masterbatches for POM are based on low-emission carriers.

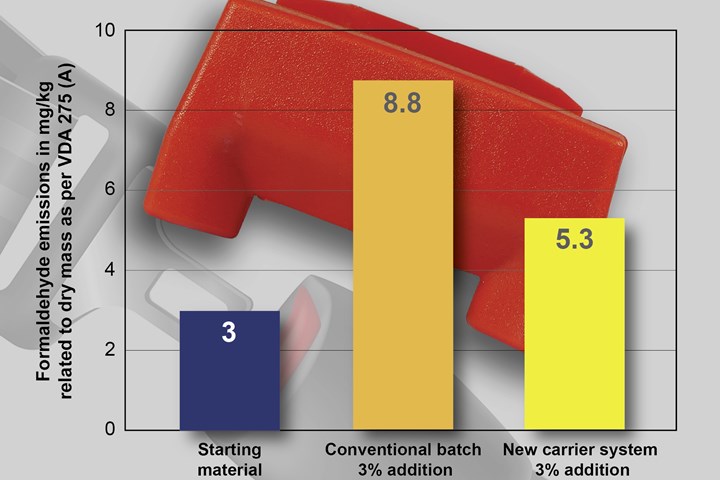

Functional and combination color masterbatches for acetal (polyaxymethylene-POM) based on low-emission carriers are newly available from Israel’s color and white masterbatch producer Tosaf Color Service (U.S. office in Bessemer, N. C.). In addition, the pigments have been optimally selected with regard to their effectiveness. As a result, the low emission data of the starting material--depending on the POM type, are reportedly almost fully retained, even after coloring and compounding.

Tosaf’s new masterbatches are said to help ensure compliance with the strict specifications of the automotive industry for molded parts, and also with the requirements regarding personnel safety. The emission-optimized masterbatches are suitable for all POM grades. According to Tosaf, at customer request, ongoing applications can also be switched to the new technology.

Tests carried out at an independent institute show the efficiency of the adopted measures, based on the example of a conventional, low-emission POM grade, to which a combination masterbatch was added. By switching from the conventional masterbatch to one with optimized color pigment and carrier material, the formaldehyde release was reduced from non-permitted 8.8 ppm to a very good rate of below 6 ppm.

The portfolio of low-emission POM masterbatches offered by Tosaf ranges from grades in standard and customized colors through functional versions—e.g., with lubricants, UV or heat stabilizers, to combination grades with or without a color component. Typical applications beyond automotive interior/exterior parts and conveyor technology include components for office and entertainment electronics, as well as white goods including small and large kitchen devices.

Said sales manager Andreas Kruschinski, "With the consistently high batch-to-batch quality level of our masterbatches, and because of their ease of handling, our new low-emission grades are gaining a growing number of authorizations and are also registering the first series applications for car interiors. Schauenburg Industrietechnik GmbH is one of our pilot customers in this area. In addition, we are experiencing growing demand in all typical POM applications in a wide variety of industries."

Related Content

-

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

-

Polymer Science for Those Who Work With Plastics: Why Entanglements — Not Just Molecular Weight — Drive Plastic Performance

Ever try running your fingers through tangled hair? Yeah … that’s not fun, but that’s what happens at the molecular level when polymer chains reach the right length. They wrap around each other, intertwine and … get stuck — and those tangles are the real reason plastics perform the way they do.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 2

For the vast majority of thermoplastics, the stability of the materials can be stated in years, not months. But there are exceptions where shelf life can be a serious issue.