ZAG Equipment Sales Partners with Portugal’s Plasdan of Portugal

Under the agreement, ZAG will sell and service Plasdan’s add-on injection units and fully electric rotary tables for multicomponent injection molding.

ZAG Equipment Sales (Gibsonville, N.C.) has entered an agreement with Plasdan Automação e Sistemas (Marinha Grande, Portugal) giving ZAG exclusive sales rights for Plasdan’s multi component injection molding products in the U.S. Plasdan manufactures add-on injection units and fully electric rotary tables, in addition to turnkey in-mold assembly systems that can eliminate press-side automated assembly.

Plasdan’s auxiliary injection units can be retrofitted into an existing molding cell to allow multicomponent molding.

Photo Credit: ZAG

In a release, ZAG President Tim Gould said Plasdan’s multi-material molding technologies can be retrofitted to existing molding machines, as well as be integrated in new cells, partnering with injection molding machinery manufacturers and mold makers.

ZAG currently maintains a Plasdan multicomponent injection molding system at its technology center in Gibsonville for technology demonstrations and application development. ZAG notes that its sales engineering staff is available to advise injection molding companies and brand owners with new ways to implement multi-material molding. All of Plasdan’s products are domestically supported by ZAG’s service technicians, with spare parts also located at the Gibsonville facility.

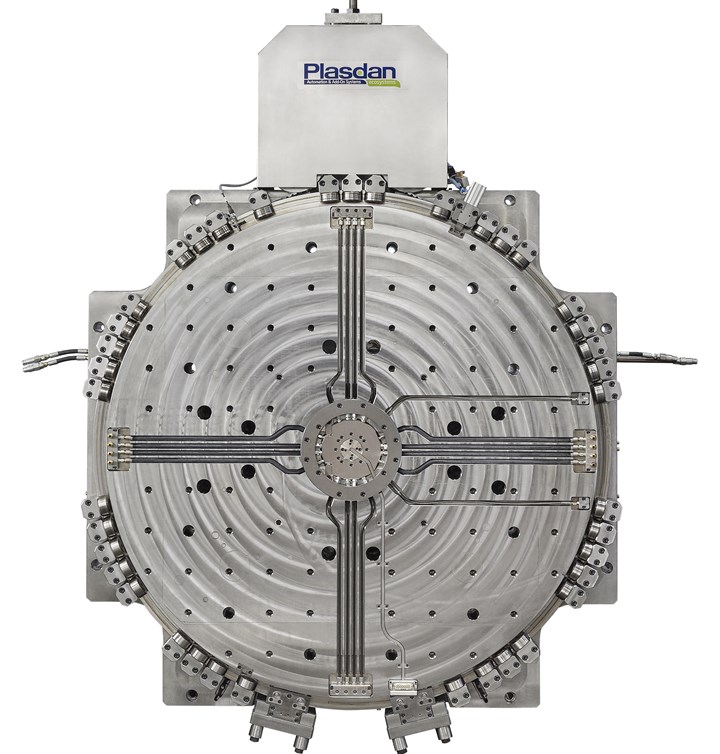

Plasdan manufactures servodriven rotary tables to support multicomponent injection molding.

Photo Credit: ZAG

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Use These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.