VTT Develops Biobased PEF from Pectin-Containing Agricultural Waste

The carbon footprint of plastic bottles can be lowered by 50% says VTT technical research center when replacing their raw PET material with PEF made from citrus peel and sugar beet pulp.

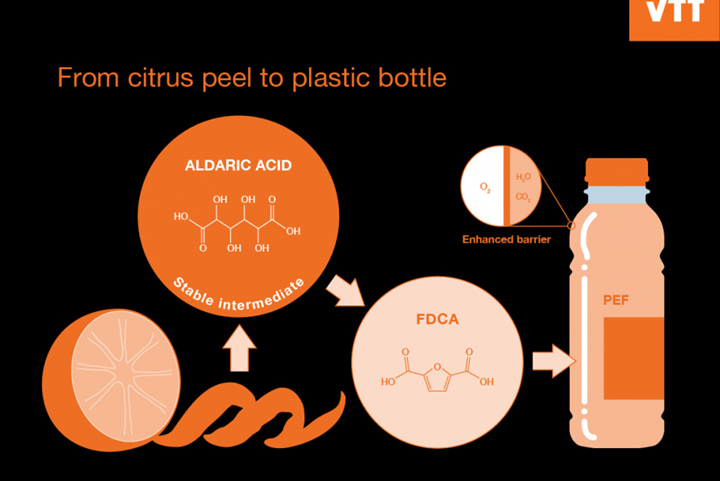

New technology developed by Finland’s enables the use of pectin-containing agricultural waste, such as citrus peel and sugar beet pulp, as a raw material for biobased PEF (polyethylene furanoate) for replacing fossil-based PET.

According to VTT, replacing fossil-based PET with plant-based PEF polymers can lower the carbon footprint of plastic bottles and food packaging by 50%. “In the near future, you may buy orange juice in bottles that are made of orange peel. VTT’s novel technology provides a circular approach to using food waste streams for high-performance food packaging material, and at the same time reducing greenhouse gas emissions,” explained VTT professor of practice Holger Pöhler.

Moreover, the barrier properties of PEF plastic have been shown to surpass those of PET, translating to a longer shelf life for food products. The VTT technology boasts significant advantages for making biobased PEF. It uses a stable intermediate for the production of FDCA (2,5-furandicarboxylic acid), one of the monomers of PEF, which reportedly enables a highly efficient process. In addition, utilizing pectin-containing waste streams opens up new possibilities for the circular economy of plastics.

VTT’s unique scale-up infrastructure from laboratory to pilot scale ensures that its newly patented technology will be brought to a technology readiness level that will allow polymer manufacturers’ easy transition to full scale.

Related Content

-

Let's Take a Journey into the World of Molding Thermosets – Part 1

There are many fundamental differences between thermosets and thermoplastics, from the way raw materials are furnished to the molder and the process in which parts are molded.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 2

For the vast majority of thermoplastics, the stability of the materials can be stated in years, not months. But there are exceptions where shelf life can be a serious issue.

-

Polymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

What are the basic building blocks of plastics and how do they affect the processing of that material and its potential applications in the real world? Meet the repeat unit.