Thermally Conductive Nylon 6 for Electric Sports Car Component

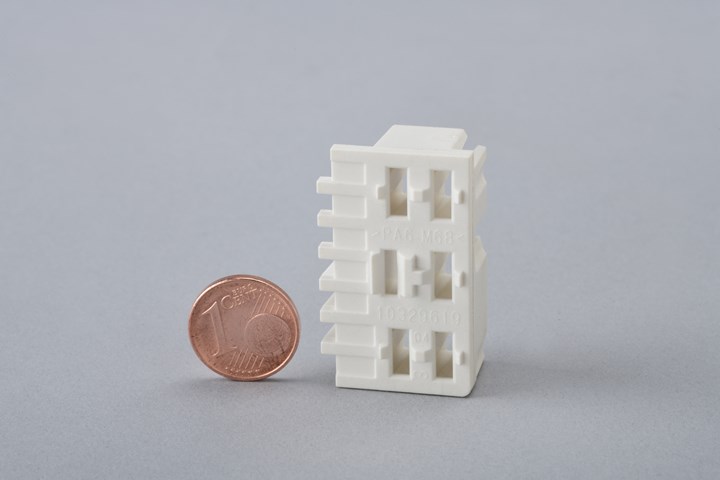

Cooling element for the charge controller of an electric sports car made from Lanxess’ Durethan BTC965FM30 nylon 6

Thermally conductive plastics are showing significant potential for use in thermal management of charging systems for electric vehicles. One recent example is the charge controller in the fully electric vehicle of a sports car manufacturer based in southern Germany. This controller contains a cooling element made of the thermally conductive and electrically insulating nylon 6 Durethan BTC965FM30 from Lanxess which dissipates the heat generated in the plug contacts of the controller when charging the batteries. Aside from preventing the charge controller from overheating, this structural material meets the strict requirements for flame-retardant properties, tracking resistance and design, according to technical key account manager Bernhard Helbich

The manufacturer of the entire charging system for the sports car is Leopold Kostal GmbH & Co. KG of Luedenscheid, a global system supplier of automotive, industrial and solar electrics as well as electrical contact systems. Charge controllers convert the three-phase or alternating current fed in from the charging station to direct current and control the charging process. During the process, they limit the charging voltage and current to prevent overcharging of the battery, for example. A current with an amperage of up to 48 amps flows through the plug contacts in the charge controller of the sports car, causing significant generation of heat during charging. “Our nylon is filled with special mineral heat-conducting particles that conduct this heat efficiently away from the source,” says Helbich. These particles give the compound a high thermal conductivity of 2.5 W/m∙K in the direction of melt flow (in plane) and 1.3 W/m∙K perpendicular to it (through plane).

Related Content

-

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

-

NPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.