StackTeck Establishes iMFLUX Center of Excellence

The Canadian maker of high-volume molds reached out to Procter & Gamble for permission to use and share information on low-pressure iMFLUX technology after success using it to qualify a range of postconsumer recycled (PCR) resins.

High-volume injection mold tooling manufacturer StackTeck Systems Ltd., Brampton, Ontario, is now supporting the iMFLUX low-pressure injection molding process to help its customers meet the challenges of molding recycled materials. Following successfully using this patented technology to qualify a range of postconsumer recycled (PCR) resin grades, StackTeck said it received permission from Procter & Gamble, where the technology was patented, to use and share StackTeck’s experience with molders that have iMFLUX-capable machines. In 2023, P&G changed its 大象传媒 strategy for iMFLUX going forward.

StackTeck notes that in its experience, iMFLUX has proven capable of handling large and sudden material property variations in real time. In a release, Jordan Robertson, VP 大象传媒 development and marketing at StackTeck, recounted watching iMFLUX’s Automatic Viscosity Adjustment capability handle going from a polypropylene with a melt-flow index (MFI) of 40 to a 5 MFI polypropylene with no shorts or scrap parts. “Based on many years working with PCR resins for thinwall, PCR, horticultural products, the power of this technology was immediately evident,” Robertson says.

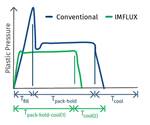

The iMFLUX process utilizes a closed loop control system to manage injection pressure during every molding cycle based on real-time measurement of the molten plastic in front of the screw. Pressure measurements are taken at a frequency of 1,000 hertz, and the control system maintains a constant injection pressure, regardless of potential variations caused by material changes over time.

StackTeck President and CEO Vince Travaglini says that in coming years, he sees PCR applications growing from a few molds per year to a substantial proportion of the projects that StackTeck will be handling. “As a result, we are working to adapt our mold test machines and qualification procedures to suit PCR projects, while also preparing to handle more projects for PCR resin qualifications,” Travaglini said.

StackTeck began trialing molds running PCR on a 640-ton Sumitomo Demag press equipped with iMFLUX technology. Source: StackTeck

Related Content

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.