Recycling Program Announced for Nylon 3D Printed Parts

Sculpteo, part of the BASF company, announced a program to establish a circular material stream with its recycling program for 3D printed products.

, a 3D printing service provider and part of BASF chemical company, announced a new take-back program, branded “RE-cycleo”, that will recycle 3D printed parts returned by its customers.

End of life 3D printed parts can be returned for recycling.

Photo Credit: Sculpteo

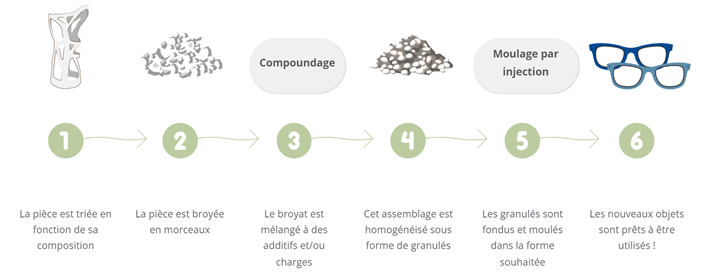

Clients will be able to send nylon PA11 and PA12 3D printed parts back to Sculpteo with a destruction authorization. Sculpteo will sort and grind the parts before sending the material on to its partner Arkema, where it will be compounded and pelletized as part of Arkema’s Virtucycle program. The new material will be used in various industrial applications. Production scrap will also be accepted.

Process diagram for the RE-cycleo concept.

Photo Credit: Sculpteo

The entire process is completed using 100% renewable energy, says the company. RE-cycleo is part of Sculpteo’s strategy to offer more sustainable solutions, which also includes expanding its line of sustainable materials such as biosourced PA11.

Related Content

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.