Novomer Achieves Breakthrough in Development of Low-Cost Compostable Polymers

Novomer expects strong economics and scalability of its Rinnovo PHA to meet circular economy demands of brand owners.

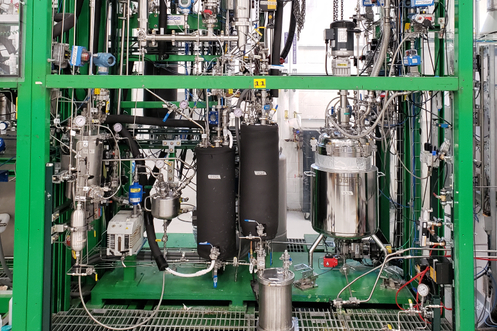

What is touted as the industry’s lowest-cost polymerization process to make compostable polymers that satisfy brand owner requirements for circular economy solutions was recently demonstrated successfully by ., Rochester, N.Y.

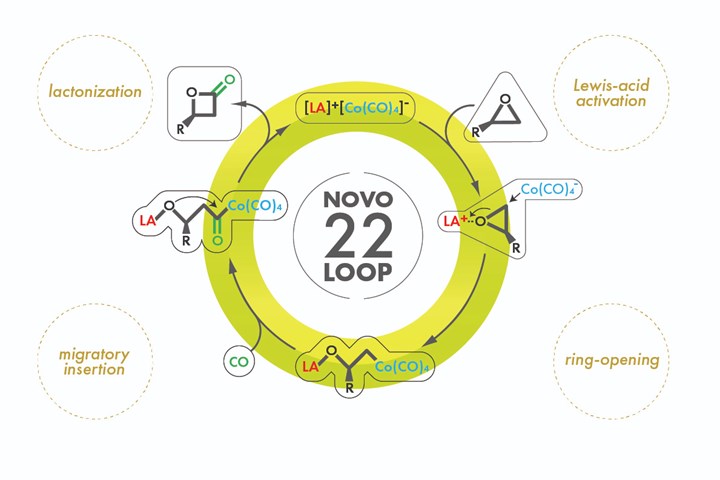

Named Rinnovo, the new polymer is a polyhydroxyalkanoate (PHA) that is synthesized using proprietary and highly selective catalysts, enabling scale and cost advantages over incumbent routes to compostable polymers. Rinnovo is produced via Novomer’s patented COEth technology which is designed to convert ethylene oxide and carbon monoxide to produce lactones. The company’s demonstration plant utilizes a low-cost initiator to facilitate ring opening polymerization. Under the conditions of chain propagation, Novomer has achieved molecular weights required for commercial applications.

The compostable material is currently being manufactured in sample quantities at Novomer’s Rochester Innovation Center. The technology’s successful demonstration will enable Novomer to begin the design and engineering of a commercial facility, allowing Novomer to commence construction of an intended 80,000-tonne facility in 2022.

Said Novomer CEO Jeff Uhrig, “As a company focused on scalable materials for the circular economy, Novomer has committed significant resources towards its mission to cost effectively address the plastic waste challenge. Further, the seemingly unstoppable rise in ocean plastic waste and microplastics will require a portfolio of solutions to confront a wide variety of regional, techno-economic, and socio-economic challenges. We are beyond excited that our technology can lower the cost barrier to implement changes needed in the plastic waste management infrastructure. Brand owners need assurances that compostable solutions can be cost effective and scaled. This is an exciting first step to begin the process of product performance validation and application development.”

Rinnovo has been tested and meets the requirements of ASTM D6400, the U.S. standard specification for compostable plastics, along with the EU’s EN13432 directive for compostable and biodegradable packaging. Rinnovo is flexible and provides over 500% elongation for the production of blown film while it reportedly also offers higher tensile strength than polyethylene. Novomer sees broad use for Rinnovo compostable polymers in a range of applications including bags, labeling, agricultural films, and waste packaging.

“Ultimately, the mission of Rinnovo materials is not only to provide sustainable end-of- life outcomes for polymers but support even broader initiatives to enhance collection and composting of food and agricultural waste, improve soil quality, and reduce global emissions,” said Uhrig.

Related Content

-

Research Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

BASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.