Nova Chemicals and Enerkem Advance with Chemical Recycling Technology

The ‘partners’ are closer to commercialization with the move to pilot stage in Edmonton, Alberta.

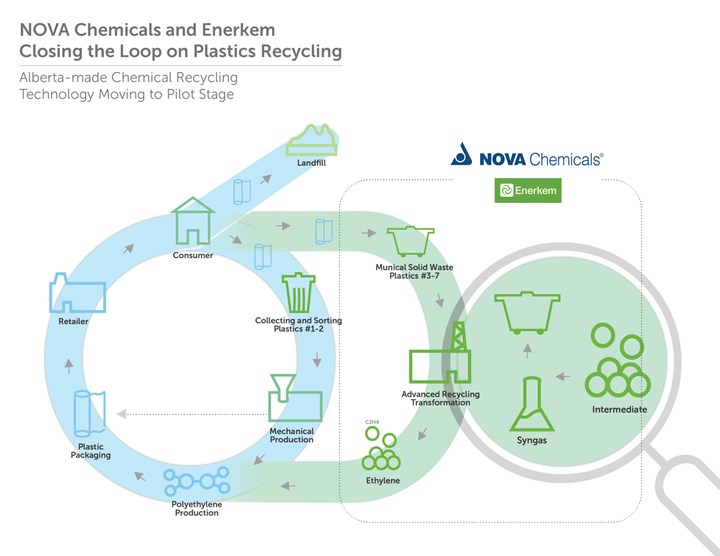

Thanks in part to CDN$4.5 million from Alberta Innovates, Nova Chemicals and are advancing their versatile and energy efficient chemical recycling technology to pilot stage in Edmonton, Alberta.

The funding, provided through Alberta Innovates’ Technology Innovation and Emissions Reduction (“TIER”) Economy Recovery Program has enabled the ‘partners’ to expedite construction of a pilot-scale reactor system that converts syngas produced from used, non-recyclable and non-compostable plastics to feedstocks for virgin-grade plastics.

The Nova/Enerkem team of experts has been working to achieve lower greenhouse gas emissions while significantly accelerating the upgrading process for waste materials. The project leverages the gasification expertise of Enerkem--a world-leading waste to renewable fuels and chemicals producer, and Nova’s petrochemicals and plastic manufacturing experience to position Alberta as a world leader in the development of a circular economy by diverting waste from landfills, creating value-added products, and reducing greenhouse gas emissions.

Said Greg DeKunder, v.p. of Nova’s Polyethylene Marketing unit, “Nova has a bold ambition to create a plastics circular economy and work to design a low carbon, zero plastic waste future. Advanced recycling technologies are a game changing component of enabling a circular economy and achieving zero plastic waste in the environment. This joint initiative with Enerkem further demonstrates that industry collaboration will be key to providing economically viable solutions for sustainable, circular plastic production.”

Said Michel Chornet, executive v.p. of Enerkem’s Engineering, Innovation and Operations, “By taking waste streams that are otherwise non-recyclable, we can complement mechanical recycling efforts and provide an important solution to close the gap between recycling targets and the important role plastics play in our daily lives. The project aims to expand the types of materials that can be recycled and increase recycling rates while reducing emissions from incineration and landfill and keeping plastic out of the environment. It is a significant step in realizing the vision of the circular economy.”

Related Content

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

Shredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.

-

Extrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.