Materials: Glass and Carbon Fiber-Reinforced PP for Automotive

Borealis brings its Fibremod PP technology to North America which boasts flexible designs with reduced weight and cost in automotive applications,

Fibremod, an innovative carbon and glass fiber-reinforced PP technology developed by Austria’s (U.S. office in Port Murray, N.J.) is being introduced to the North American automotive market via the company’s Taylorsville, N.C. facility. This is the company first North American dedicated automotive PP compounding plant, which began operations in 2019.

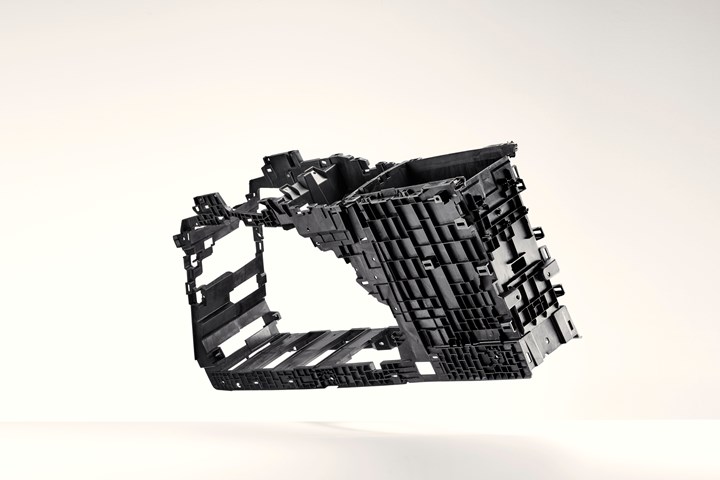

The Fibremod family of products reportedly enables automotive manufacturers to achieve weight-saving and process cost-saving targets. In turn, replacing engineering plastics and metal parts with energy-efficient and lighter weight PP grades leads to improved fuel economy and lower CO2 emissions. These customized carbon and glass fiber-reinforced PP compounds are said to be at the cutting edge in automotive manufacturing, bringing lighter weight, extra strength, and greater impact performance across applications ranging from front end and tailgate modules to instrument panel and center console carriers.

According to Borealis, the Fibremod family of compounds are a suitable material substitute for metal, and engineered plastics, delivering unmatched design flexibility. Short-glass, long-glass and carbon fiber formulations are available, with customizable fiber content ratios, to enable manufacturers to balance strength, weight, and cost according to specific design needs.

Fibremod products also support energy efficiency in production by reducing process temperatures and energy requirements compared with alternative solutions such as polyamides.

Related Content

-

Polymer Science for Those Who Work With Plastics: Why Entanglements — Not Just Molecular Weight — Drive Plastic Performance

Ever try running your fingers through tangled hair? Yeah … that’s not fun, but that’s what happens at the molecular level when polymer chains reach the right length. They wrap around each other, intertwine and … get stuck — and those tangles are the real reason plastics perform the way they do.

-

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

-

Polymer Science for Those Who Work With Plastics: Molecular Weight — What It Is and Why It Matters

Molecular weight might seem like an abstract concept, but it plays a crucial role in determining the behavior of plastics during processing and in their final applications.