Material Handling Totes from Recycled Mixed Waste Coming

UBQ material will be incorporated along with other recycled materials.

announced that a new line of logistics totes will be developed using its material, which is made from diverted landfill waste. , a member of the (CSS) Group, will manufacture the totes. , a distributor, recommended UBQ material to meet customer demand for more eco-conscious products.

UBQ material is a bio-based thermoplastic made from household waste that includes organics. The process uses a reactor to break down organic waste, which is then bonded with mixed plastics to form a thermoplastic matrix. A planned UBQ facility in the Netherlands will produce 176 million lb/yr of the material.

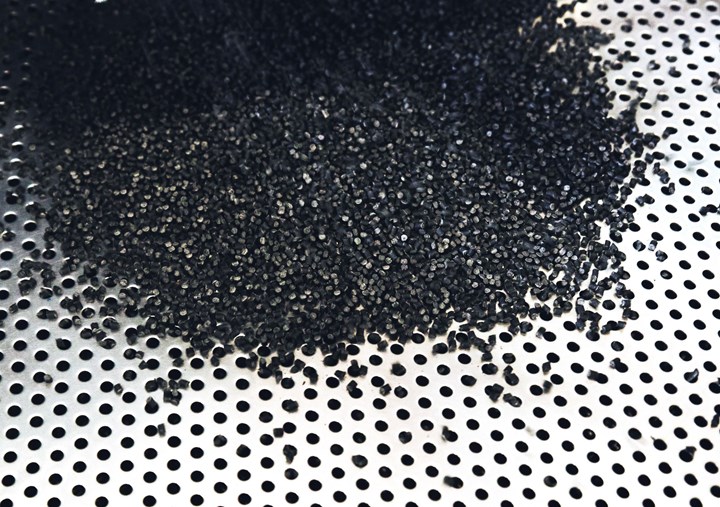

Pellets of UBQ recycled material, made from mixed plastics and organic waste.

Photo Credit: UBQ Materials

The substitution of UBQ for PP will have no noticeable impact on the physical properties of the totes, according to the company. For each pound of virgin PP replaced by UBQ material, a reduction of 11.7 lb CO2-equivalent emissions is expected.

“Corporations are committing to sustainable practices and minimizing their environmental footprint through the purchase of eco-conscious products. CSS Group’s decision to create sustainable products further strengthens this commitment and enables everyone to play a role in reducing emissions and waste,” said Jack Bigio, co-CEO at UBQ.

Related Content

-

'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.