Hard Head Veterans Adds Larger LS Mtron Machine for Safety Helmet Production

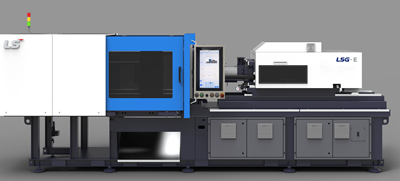

LS Mtron is providing a 420-ton injection molding machine to Hard Head Veterans for creation of tactical bump helmets and upcoming E-Class aramid fiber-infused safety helmets.

HHV Injection Molding Lead Daniel Cowart holds HHV products in front of the company’s 120-ton LS Mtron machine. Source: LS Mtron

has added a 420-ton LS Mtron injection molding machine to its manufacturing facility to create precision-engineered helmets, accessories and components.

HHV is a veteran-owned manufacturer based in Sweetwater, Texas, known for producing a growing list of ballistic helmets and tactical helmets for military and law enforcement. It also makes Kevy Safety hard hats and safety helmets, which are designed to provide durability, comfort and advanced protection.

LS Mtron says this collaboration will augment HHV’s injection molding technology in its manufacturing process, enabling the production of innovative helmets and accessories, and paving the way for HHV’s upcoming release of an E-Class aramid fiber-infused safety helmet. Class E (Electrical) hard hats are designed to reduce exposure to high-voltage conductors, and offer dielectric protection up to 20,000 volts (phase to ground).

As the first phase of the collaboration, the introduction of an E-Class aramid fiber-infused safety helmet will combine the latest in helmet technology with the precision and durability of LS Mtron’s molding equipment. Aramid fibers (short for aromatic polyamide) are a class of heat-resistant and strong synthetic fibers used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites.

This partnership builds upon the existing relationship in which HHV already utilizes a 140-ton machine to manufacture parts on a daily basis. Together, these machines will enable HHV to maintain high production standards and meet the growing demand for its premium helmets and accessories.

“Our continued partnership with LS Mtron is a game changer for us,” says Dub Robertson, plant director for Hard Head Veterans. “We’re already seeing the benefits of their 140-ton machine, which has been delivering top-quality parts daily. The addition of the 420-ton machine will allow us to scale even further, producing helmets with unparalleled precision while maintaining our commitment to U.S. manufacturing.”

Dual Injection Molding Machines

The 140-ton machine is already in use for daily production of helmet parts, and the newly added 420-ton machine will be used for the creation of tactical bump helmets and the upcoming E-Class aramid fiber-infused safety helmet. LS Mtron’s advanced technology offers precision engineering to ensure that each helmet component meets HHV’s rigorous safety and quality standards.

HHV says this partnership also reaffirms its commitment to U.S. manufacturing. By utilizing LS Mtron’s cutting-edge equipment, HHV aims to bring manufacturing jobs back to the U.S. and support domestic production.

“South Korea is a close ally of the United States, and LS Mtron’s machines benefit from 0% import duties and no tariffs, making this partnership a significant win for U.S. manufacturing looking to acquire equipment,” Robertson says.

LS Mtron is part of the LS Group, a South Korean-based conglomerate with over 25,000 employees. LS Mtron Injection Molding Machines (LS IMM), a division of LS Mtron, was started in 1969 by South Korea’s LG Corp., one of the world’s largest plastic molders. Founded initially to satisfy its own production needs for injection molded components used in its televisions, appliances, electronics and other products, today LS IMM produces around 3,000 machines per year, not only for use by its network of LS-related and LG-founded companies but also for thousands of molders around the world.

LS IMM says it can provide new custom molding machines to its customers in North America in just 100 days — from casting to cargo or even faster from its stocked inventory.

Related Content

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

Quantum Storage Systems/M&M Plastics Updates Machine Fleet

The Miami, Fl. based injection molder has ordered 11 new injection molding machines from LS Mtron.

Read MoreVertical Injection Molding Machine Range Extended

LS Mtron’s expanded range of LSG-V vertical machines has 13 models with a variety of injection and rotary table formats.

Read MoreNew Hybrid, All-Electric and Vertical Injection Molding Machines

NPE2024: In addition to new machines, LS Mtron is also launching a new 18-inch multitouch controller from Keba.

Read More