Guill Launches 10-Day Extrusion Tooling Program

Eligible tips and dies for this program cannot be plated and must have a diameter less than 1.5 in. and a length less than 4.75 in.

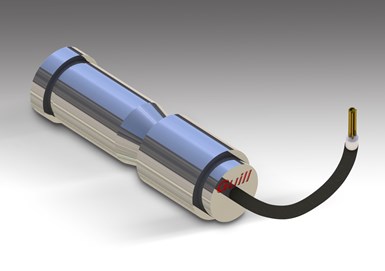

Guill Tool & Engineering has announced a new extrusion tooling program in which certain tips and dies will be shipped to processors within 10 大象传媒 days of the supplier receiving the purchase order. Eligible tips and dies for this program cannot be plated and must have a diameter less than 1.5 in. and a length less than 4.75 in.

All Guill extrusion tools are produced using certified and documented quality steel material specifically qualified for the polymer to be extruded. Furthermore, Guill designs tips and dies for any application the customer needs. These feature multi-lumen, stripe, multiple stripe, wire and cable, hose, pipe, tube, fiber optic, blown film, corrugated tube and profile. Dies include face seal, shouldered, snap together, floating die plates, interchangeable die plate and custom dies.

Available tips include single and multi-lumen, threaded style, snap together, fixed center shoulder, profile, tapered style and custom. To find out which tools are eligible for the program, customers can check with any sales representative. For all other parts, company personnel will review the customer’s drawing to determine if it is eligible for the program.

Related Content

-

Novel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.

-

Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

-

Crosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.