Germany’s IKV to Build ‘Smart Factory’ R&D Center

Germany’s leading plastics institute bids to be a world leader in Industry 4.0 technologies.

Germany’s has announced plans to build a new complex as part of a $21 million project to develop the “smart factory” concept, also known as Industry 4.0. The new 45,000-ft2 Plastics Innovation Center 4.0 (PIC4.0) will be erected adjacent to the IKV’s home at the RWTH University Aachen and should be completed by 2022. The center will pursue both R&D and training of companies and employees in digitization of plastics processing. The IKV says it aims “to become a world-leading Industry 4.0 center for the plastics industry.

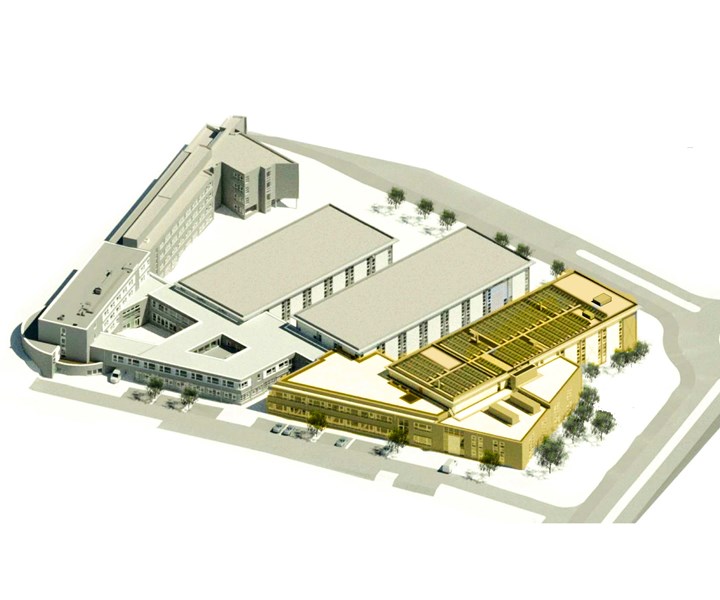

Shaded area indicates new 45,000-ft2 Plastics Innovation Center 4.0, to open in 2022.

Pascal Bibow, team leader of process control and mold technology at the IKV, has been tapped to run the center. He told Plastics Technology that although injection molding will play an important role, “We want to enable cross-domain analytics and process interconnection; we will also focus on correlations from other directly related technologies. There are plenty of possible use cases for process interconnection that cannot be represented and analyzed anywhere yet for scientific research on digitized value chains.”

Bibow said the IKV plans to relocate its injection molding department to the new building. The project will also focus on a range of ancillary processing steps, including material testing, drying and conveying, along with compounding and final quality assurance. He noted that research could also encompass production of injection molded preforms and stretch-blow molding.

Equipment suppliers and plastics processers will be included on the center’s advisory board, Bibow explained, noting that the names of participants will be released in the coming months. The German state of North-Rhine Westphalia and the European Union are funding the project.

Related Content

-

Plastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.