Engel Announces Virtual Structural Foam Molding Conference

Free, three-day foammelt conference shifts to a virtual format, providing info on all aspects of structural foam molding.

Running Nov. 17-19 in German and English, Engel has announced a free, virtual version of its , providing information on structural foam molding that Engel says is geared towards plastics processors and mold manufacturers, as well as developers and design engineers.

The range of topics presented in the virtual event will cover the entire process, from foammelt compatible component development and design, through materials and injection molding best practices, to surface quality.

Over three days, Engel says three different blocks of topics will be presented in four practice-oriented keynotes each, with German in the morning and in English in the afternoon. Engel’s Michael Fischer, head of 大象传媒 development technology, and Wolfgang Kienzl, product management technologies, will serve as hosts for the interactive event. Questions from participants will be answered by the speakers directly after the lectures.

The conference’s first day is dedicated to the technology basics and advantages of foaming. Besides comparing physical and chemical foaming, participants will see a presentation on the lightweight engineering and sustainability aspects derived from combining foaming and co-injection. At the end of the first day, Trexel will offer insights into the future development of its physical MuCell process.

Day two will focus on product development, mold engineering and quality assurance, discussing which components are suitable for structural foam molding and why tooling is crucial for the best part surface. Simulation for process optimization and new developments in inline measuring methods will also be covered.

The third day will take an in-depth look at implementation and practical experience with structural foam molding. Material supplier Borealis will present on special granulates for PP structural foam molding, while ProTec Polymer Processing will demonstrate the SOMOS Perfoamer process, in which the plastic granulate is enriched with CO2 in an autoclave before further processing. Engel and the Chase Competence Center Linz will discuss research on structural foam molding and the future of foammelt.

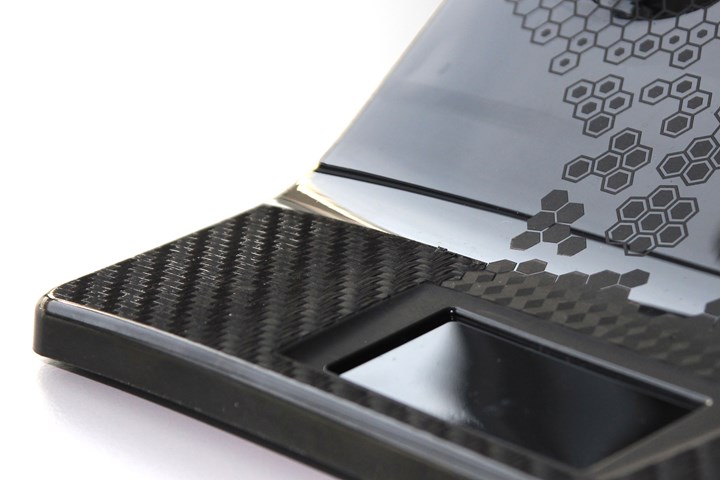

Components produced using structural foam molding can be 20% lighter than those produced using traditional injection molding.

Related Content

-

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

-

Is There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.