Eastman’s First Sustainability-Based Agreement with a Major Prestige Beauty House Involves its Chemically Recycled Renew PET Copolymer Portfolio

Eastman’s agreement with The Estée Lauder Companies expected to help drive greater use of recycled or recyclable plastics in luxury cosmetics packaging.

A global memorandum of understanding (MOU) has been signed by Eastman, Kingsport, Tenn., and NYC-based The Estée Lauder Companies (ELC) that will enable ELC to take significant strides towards its 2025 sustainable packaging goals. This is the first sustainability-based agreement between Eastman and a major prestige beauty house and it is expected to help drive the increased use of recycled and/or recyclable plastics in luxury cosmetics packaging.

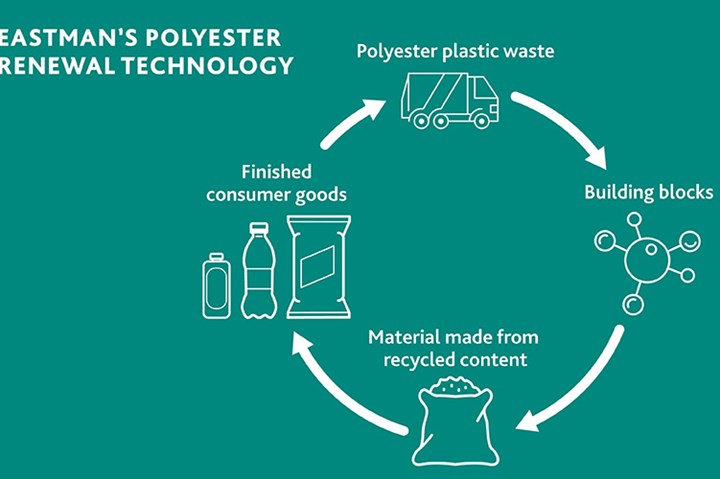

Through the agreement, ELC and its portfolio of brands will begin incorporating packaging solutions enabled by Eastman’s molecular recycling technologies and portfolio of Renew resins with up to 100% certified recycled content. Eastman’s portfolio includes a newly introduced line of molecularly recycled polyesters produced via Eastman’s Advanced Circular Recycling. These sustainable resins, which include Eastman Cristal Renew and Eastman Tritan Renew, are made using up to 100% International Sustainability & Carbon Certification (ISCC) certified recycled content and are chemically indistinguishable from their legacy counterparts. They reportedly demonstrate the same high-quality and processing ease of virgin polymers with the clarity, luster, color compatibility and durability cosmetics packaging demands—while providing premium recycled content.

Said Roberto Magana, senior v.p. and chief procurement officer for The Estée Lauder Companies. “Our suppliers play a critical role in helping The Estée Lauder Companies continue to move the needle and think innovatively about sustainability. Eastman’s molecular recycling technologies and portfolio of Renew products will help drive the achievement of the company’s sustainable packaging goals while maintaining the high-quality aesthetic, safety and performance of our prestige products. We look forward to collaborating with them.”

The MOU will further ELC’s focus on its sustainable packaging goals. The company has committed that, by 2025, 75-100% of its packaging will be recyclable, refillable, reusable, recycled or recoverable. Additionally, the company will increase the amount of post-consumer recycled material in its packaging by up to 50% in the same year.

Said Scott Ballard, Eastman’s v.p. and general manager for the specialty plastics division. “We are proud to partner with The Estée Lauder Companies, one of the world’s most iconic prestige beauty companies and a true leader in sustainability. We are excited to help them achieve their ambitious sustainability goals right now. Together, we can provide a shining example of what is possible today—not years in the future—to advance the circular economy.”

Related Content

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

-

Plastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.