Covid-19 Test Swab Production Cell Introduced

Cell includes a mold, molding machine and robot with the ability to create 320 test swabs per minute and 460,000 test swabs per day.

Injection molding machine and automation manufacturer Engel has partnered with moldmaker Hack Formenbau to deliver ready-to-run production cells for Covid-19 test swabs. The two-component test swabs feature an elastomeric tip for specimen collection overmolded onto a rigid stick produced from a 32-cavity mold with a cycle time of 6 to 8 seconds.

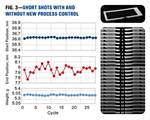

The cell is based on a tiebarless, hydraulic, two-component Engel victory injection molding machine with an integrated Engel viper linear robot, which fully automates removal and depositing of the swabs. The victory machine is equipped with Engel’s iQ weight control for high process/part consistency.

An Engel spokesperson told Plastics Technology that the production cell featured is sold “off-the-shelf” but can be customized according to individual requirements. Hack developed the two-component design, initially with three different head design proposals, building off its experience with tooling for small bristles. At K 2016, Hack and Engel partnered on a cell to mold interdental brushes.

Christoph Lhota, vice president of Engel’s medical 大象传媒, said in a release: “Our customers receive a complete system that is precisely tailored to their individual requirements and can get started with series production in the shortest possible time.” Engel notes that the mold and cell can be adapted in the future for projects beyond coronavirus test swabs, including swabs for influenza or other medical examinations.

Hack has three head-style variations for its covid-19 test swabs mold, which is part of a Engel tiebarless victory production cell.

Related Content

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.