Covestro PC Chosen by Dermadry for Treatment Trays of Medical Device

Makrolon 2458 PC makes up key components of the latest device for treating hyperhidrosis.

A polycarbonate from was chosen by Dermadry Laboratories, a leading manufacturer of iontophoresis machines for at-home treatment of excessive sweating. Hyperhidrosis, characterized by excessive sweating, affects approximately one in 20 people worldwide. Dermadry selected Makrolon 2458 PC from Covestro to form an important component of its latest Dermadry Tap Water Iontophoresis (TWI) device.

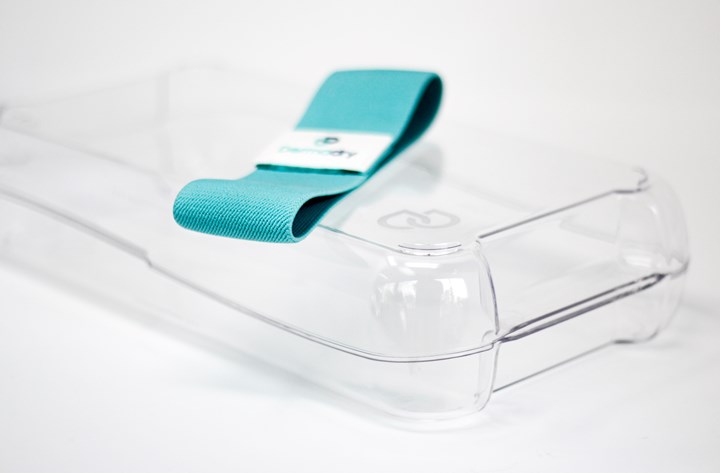

Dermadry offers three tailored TWI solutions to treat the areas most commonly affected by hyperhidrosis: the hands, feet, and underarms. Through extensive research, Dermadry found existing treatment devices were complicated to use, took up a lot of space, and looked too technical. With its latest iteration, Dermadry set out to design a user-friendly, ergonomic and aesthetically appealing device. The all-in-one Dermadry Total machine addresses these while halting sweat production by using the passage of mild electrical current through tap water to disrupt the signal between the nerves and sweat glands. The device’s treatment trays that utilize Covestro PC are designed to make iontophoresis treatment easier and more comfortable for the user, and can also be interlocked, forming a convenient, compact storage case for all device pieces.

The Dermadry team evaluated several different materials for the treatment trays, including ABS and PP, before choosing Makrolon 2458 PC. The team found that this medical PC grade offers the required physical properties, including excellent impact resistance, clarity, quality and biocompatibility —complemented by the strong aesthetics required for this application — a glossy finish and ergonomic design.

Said Dermady marketing director Mathieu Mireault, “We sought a biocompatible material for intact skin, beyond the standard properties of polycarbonate resins. Thanks to Makrolon, Dermadry was able to design a product that evokes wellness and offers a soothing experience. Covestro’s excellent reputation, and ISO10993 testing, sealed the decision.”

Related Content

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

-

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

-

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.